How Does Horizontal Directional Drilling Work?

Horizontal Directional Drilling (HDD) is a trenchless method used to install underground pipes and conduits with minimal surface disruption. The process is carefully planned to avoid existing utilities and environmental obstacles, and consists of three key phases: drilling a pilot bore, reaming the hole, and finally, installing the pipe.

It begins with the excavation of an entrance pit at the launch site. This pit serves as a base for managing drilling fluid—a specially formulated mixture of water and bentonite clay. The fluid is pumped to the drill head to cool and lubricate the drilling assembly, while also carrying away soil and cuttings to maintain a clean bore path.

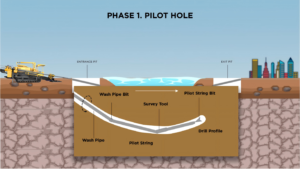

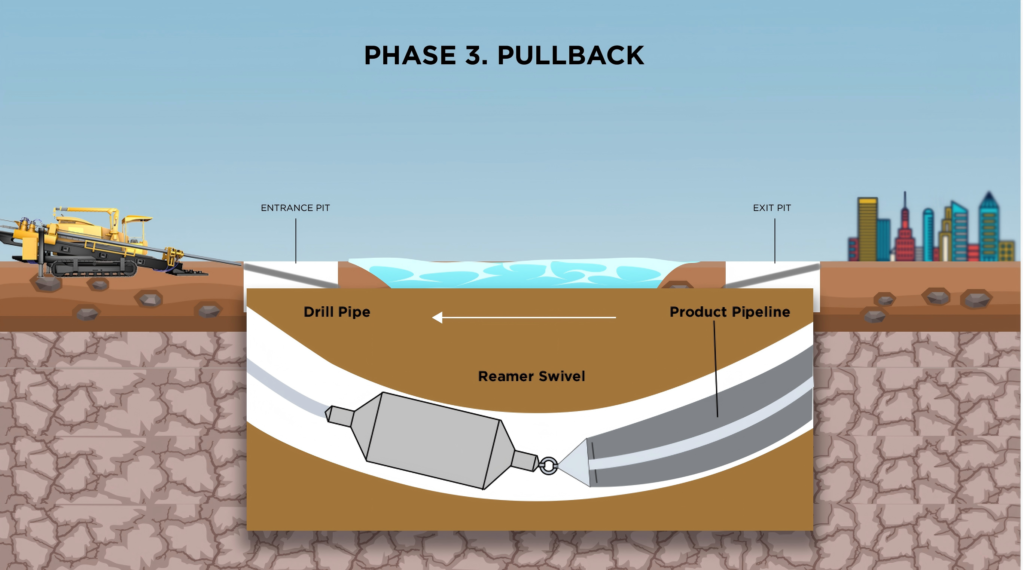

At the exit point, a receiving pit is dug to complete the bore path. The first operational step involves drilling a small-diameter pilot hole along the designed trajectory. Tracking equipment is used throughout to ensure accuracy. Once the drill head reaches the receiving end, the pilot phase is complete.

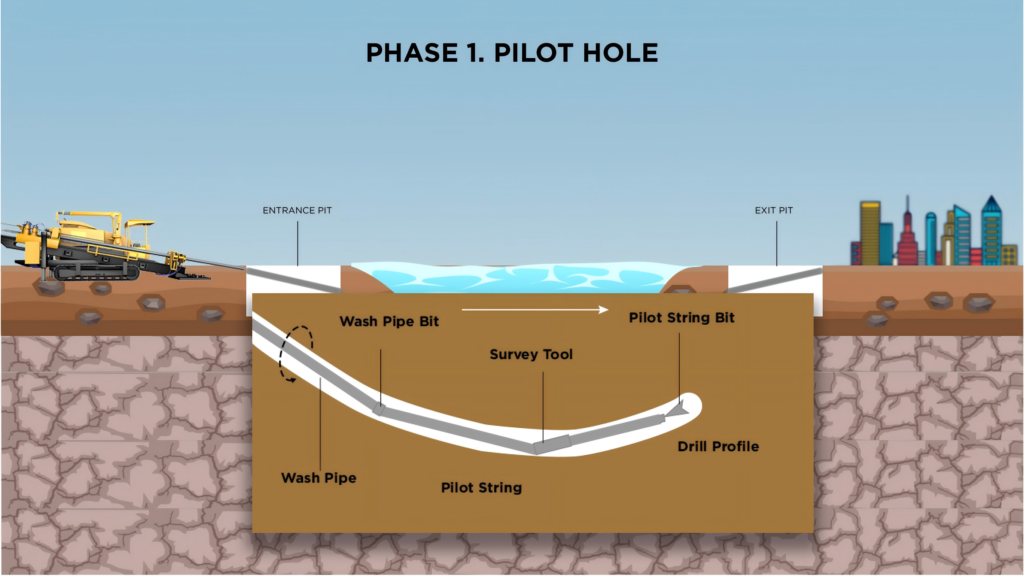

Next, the drill bit is replaced with a reaming tool. This tool is pulled back through the pilot hole, gradually enlarging it to approximately 1.5 times the diameter of the product pipe. Depending on project requirements, multiple reaming passes may be needed to achieve the desired size.

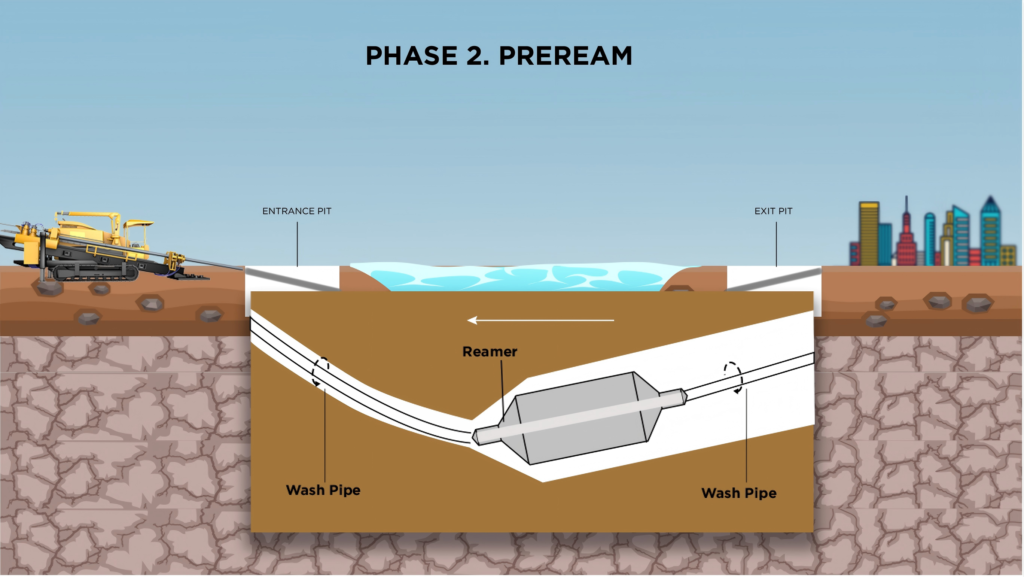

In the final stage, the pipe or conduit is prepared above ground at the receiving pit—often pre-assembled and pressure-tested. It is then connected to the reamer via a specialized swivel, which allows the reamer to rotate independently. This prevents torsion from transferring to the pipe during pull-back, ensuring a smooth, twist-free installation.

Once completed, the new pipeline rests underground, connecting the entrance and exit pits, ready for service with no visible disruption along its path. HDD offers an efficient, environmentally friendly solution for modern infrastructure projects.

Add a header to begin generating the table of contents

SHARE:

More Posts for You

- What Is the Role of HDD Drill Rods?

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?