How Ditch Witch and Vermeer Directional Drills Power Modern Fiber Optic Installation?

If you’ve ever wondered how fiber optic cables are installed underground without turning entire streets into construction zones—you’re not alone. The answer often lies in a remarkable piece of equipment: the directional drill. Among the most trusted names in the industry are Ditch Witch and Vermeer.

In this post, we’ll break down how these machines work and why they’re a game-changer for fiber optic projects and other utility installations.

What Is a Directional Drill?

A directional drill—like those made by Ditch Witch and Vermeer—is a specialized machine used in Horizontal Directional Drilling (HDD). This trenchless method allows contractors to install utilities underground with minimal surface disruption. That means less noise, less mess, and no need to tear up roads or landscapes.

How Does It Work? Step by Step

Planning the Path

Before any drilling begins, operators use advanced electronic locating systems to map out the bore path. This helps avoid existing utilities and ensures the drill follows the right depth and direction.

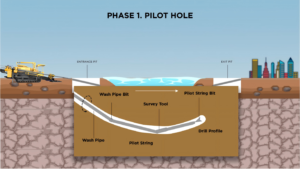

Drilling the Pilot Hole

A small, steerable drill head starts the process. It’s attached to a series of drill pipes and can be guided through soil and rock. Operators above ground monitor its position in real-time and adjust as needed.

Pumping Drilling Fluid

A mixture of water and bentonite (a type of clay) is pumped through the drill pipe. This fluid:

- Cools the drill bit

- Carries away cuttings

- Helps stabilize the borehole

- Reduces friction during later stages

Reaming the Hole

Once the pilot hole is complete, a reamer is attached to enlarge the tunnel to the desired diameter—usually about 1.5 times the size of the conduit being installed.

Pulling Back the Conduit

Finally, the fiber optic conduit (or other utility pipe) is attached to the reamer and pulled back through the bore. The result? A neatly installed utility line with almost no visible trace on the surface.

Key Components of a Directional Drill

✅ Drill Head & Bit: Cuts through soil and rock.

✅ Mud Motor: Uses drilling fluid to rotate the bit.

✅ Drill Pipe: Connects the drill rig to the head.

✅ Locator System: Tracks depth, position, and angle.

✅ Hydraulic System: Provides the power for thrust and pullback.

✅ Fluid System: Mixes and pumps drilling mud.

Why Contractors Prefer Ditch Witch & Vermeer for Fiber Optics

- Precision: Advanced guidance systems ensure accurate installation.

- Efficiency: Faster than open-trench methods, saving time and money.

- Minimal Impact: Perfect for urban areas, parks, and sensitive environments.

- Adaptability: Works in various ground conditions—from soft clay to hard rock.

Ditch Witch and Vermeer directional drills are more than just heavy machinery—they’re essential tools for building the infrastructure of tomorrow, today. By enabling fast, clean, and precise underground installations, they help bring high-speed internet and other utilities to communities with minimal disruption.

Whether you’re in the industry or just curious about how things work—we hope this glimpse into the world of trenchless technology was helpful!

Feel free to share or comment below with any questions.

SHARE:

More Posts for You

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40