The Backbone of the Bore: Understanding the Strength of HDD Drill Pipe

When you see a huge pipeline snaking through the ground or a fiber optic cable that looks like it goes right through a river, that’s the magic of Horizontal Directional Drilling (HDD).

But this amazing piece of engineering didn’t just happen. The drill pipe is a very important part of every successful HDD operation, but it is often overlooked.

HDD drill pipe is more than just a steel tube; it’s the most important part of the drilling process. It carries power, data, and hydraulic fluid, and it has to be strong enough to handle a lot of stress. Let’s talk about why this piece of equipment is so important.

What is an HDD Drill Pipe?

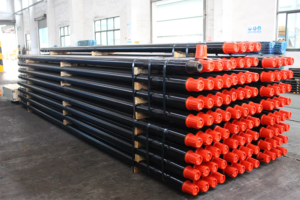

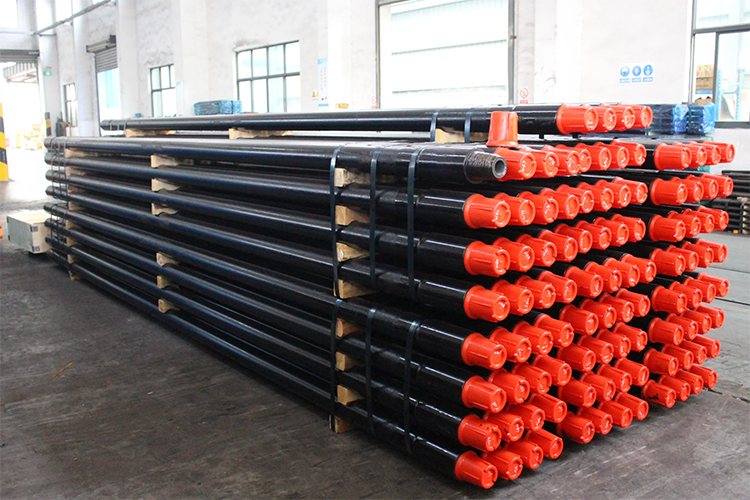

HDD drill pipe is a special type of thick-walled tubular steel that is made to meet the needs of directional drilling. It connects to make the “drill string,” which goes from the rig, through the bore path, and up to the cutting tool or reamer.

The main things it does are:

Transmit Torque and Thrust: It sends the HDD rig’s powerful rotational force and forward and backward push to the drill bit.

Convey Drilling Fluid (“Mud”): The hollow pipe is a high-pressure pipeline for drilling fluid. It cools the bit, brings cuttings to the surface, and keeps the bore hole stable.

Enable Steering: It holds the wireline or electronic steering system for pilot holes, which guides the drill bit along the planned path with perfect accuracy.

Key Features and Design: Made for the Battle Underground

Not all pipes are the same. HDD drill pipe is made to work better than other types of drill pipe:

High-Torque Tool Joints: The pipe’s most important part is the threaded connections at each end. They are made with precision and often have special thread forms, like double-start threads, that can handle a lot of twisting stress and make connections quickly and reliably. Premium grades are hardened to resist wear.

Strength and Flexibility: It needs to be very strong so that it can be pulled back with heavy product lines and flexible enough to go around curved bore paths without permanently changing shape. This is done with certain steel alloys and heat treatment.

Wear Protection: Being in contact with soil, rock, and the borehole wall all the time causes wear. Hardbanding is a layer of very hard, wear-resistant material that is welded around the tool joints and sometimes the pipe body to make them last longer.

Internal Coating: A smooth, long-lasting internal coating reduces friction loss for drilling fluid, which makes the hydraulic system work better and lowers pump pressure.

Different kinds of HDD drill pipe

The size of the job determines the type of pipe:

Small-Diameter Pipe: Used to install utilities like power, gas, and telecom. Less heavy, more flexible, and often moved by hand or with small rigs.

Large-Diameter Pipe: Used for big infrastructure projects and crossing rivers with big pipelines. It has very thick walls and huge outer diameters (like 6 5/8″), and it needs heavy-duty handling equipment.

The Process of Making and Caring for

HDD pipe of high quality goes through a lot of steps to make sure it is strong, including forging, heat treatment, threading, and non-destructive testing (NDT). But that’s not the end of its care. You have to inspect and maintain things properly. This includes:

Cleaning threads after each use.

Using thread compound to stop galling and make sure the seal is tight.

Checking for cracks, straightness, and thread wear on a regular basis.

Tracking fatigue cycles, since every bend and stress cycle adds to metal fatigue.

The Importance of the Right Drill Pipe

Choosing the right type of drill pipe is a direct investment in the safety and success of the project. If you use the wrong pipe, it can:

Costly Downtime: String failures or connection problems can stop a project for days.

Lost Tooling: If a string breaks, you might have to leave behind expensive downhole tools like bits, reamers, and locators.

Project Failure: If a drill string fails, the worst thing that can happen is that the bore will be incomplete or unusable.

The Unsung Hero: Conclusion

The HDD rig gets all the attention, but the drill string does the hard work underground. It is a work of art in metallurgy and engineering that combines brute force with precise control. It’s not just a tool for drilling contractors; it’s a key part of their business.

Buying high-quality HDD drill pipe and taking care of it well isn’t a cost; it’s the key to building a reputation for dependability, efficiency, and success in the tough field of trenchless technology.

Next time you see a new utility line going in without a trench, think about the amazing journey and the strong, smart pipe that made it happen.

SHARE:

More Posts for You

- How ZHE HDD Drill Pipes Make Your Ditch Witch JT100 Work Better and Better

- ZHE HDD Drill Pipes Will Help Your JT2720 Work Better

- Are You Using the Right Barrel Reamer for Your HDD Projects?

- How Ditch Witch and Vermeer Directional Drills Power Modern Fiber Optic Installation?

- What Is the Role of Mud Pump in Horizontal Directional Drilling Field?

- The Backbone of the Bore: Understanding the Strength of HDD Drill Pipe

- How to Choose the Right Welded Cone Hole Opener?

- What Are the Key Considerations for Trenchless Reaming Operations?