All Terrain Drilling: The Smarter Way to Drill Through Rock

In today’s HDD projects, contractors often face a tough challenge: how to drill efficiently through rock without high costs, complex setups, or environmental concerns. All Terrain drilling technology offers a fresh approach—delivering more power with less fluid, simpler equipment, and greater precision.

What Is All Terrain Drilling Technology?

All Terrain technology is a innovative HDD method designed for enhanced performance in rock drilling. It works with low fluid levels, which means less mess, shorter cleanup time, and reduced environmental impact.

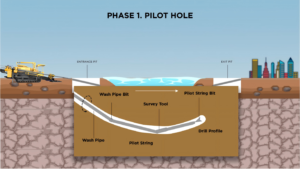

Here’s how it works:

- The inner pipe acts like a mechanical motor, rotating the drill string during pilot boring.

- The outer pipe pushes the drill bit forward and provides steering control.

- During backreaming, the outer pipe efficiently transfers machine torque downhole.

This dual-pipe, hard-connected system replaces traditional soft-connected mud motor setups—and the difference is game-changing.

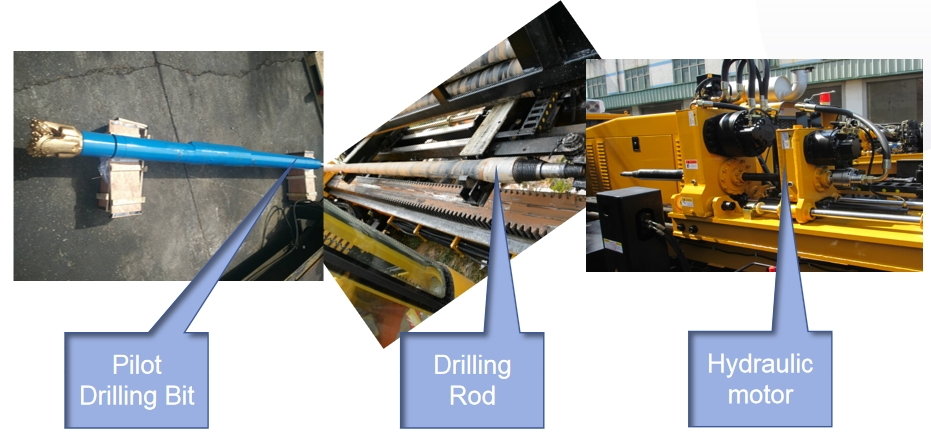

All Terrain Drill Structure

Key Advantages of All Terrain Drilling

More Torque, More Speed, Better Efficiency

Traditional mud motors use a “soft connection” system. This leads to:

- Significant pressure loss in drill pipes and water lines.

- 5% mandatory mud leakage for motor cooling.

- Internal leakage caused by wear of the stator and rotor.

Soft Connection System

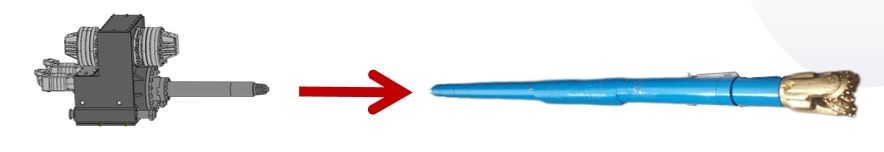

All Terrain drilling uses a hard-connected drive. The inner rod directly powers the drill bit—no screws, no stators, no unnecessary loss of energy.

Hard-Connected Drive

✅ Result: Higher effective torque, faster penetration, and better fuel efficiency.

Uses Less Mud, Cuts Costs

With All Terrain drilling, there’s no need for a mud motor. That means:

- Lower mud consumption

- Reduced fuel use

- Less wear on drilling tools

- Savings on labor and fluids

More Accurate Steering

The All Terrain pilot assembly is compact—only about 80 cm from the bit to the probe chamber. This shorter setup allows for tighter control and more precise guidance, especially useful in changing formations or when adjusting drill paths.

Probe Chamber Position

Tolerates Higher Sand Content

Mud motors are sensitive. They require bentonite with sand content below 0.5%—a standard difficult to maintain on real job sites. High sand content wears down the stator rubber, slashing motor life from 150 hours to 80 or less.

All Terrain systems don’t use a mud motor. The inner rod drives the bit mechanically, so sand content isn’t a failure point.

✅ Result: Longer tool life, fewer replacements, more uptime.

Handles a Wide Range of Rock Drilling Jobs

Thanks to its short, responsive pilot assembly, All Terrain technology offers excellent maneuverability. It’s ideal for:

- Rock drilling up to 100 meters

- Projects requiring frequent angle changes

- Urban sites with limited space or strict precision requirements

Why More Contractors Are Making the Switch?

As project conditions get more complex and cost control becomes essential, All Terrain drilling is gaining popularity—especially for short- to mid-length rock drilling. It’s a robust, simple, and cost-effective alternative to high-maintenance mud motor systems.

SHARE:

More Posts for You

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40