Barrel Reamers Plays An Important Role in Modern HDD Operations

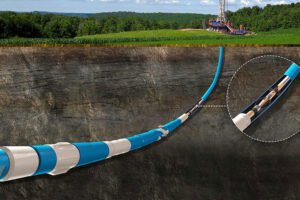

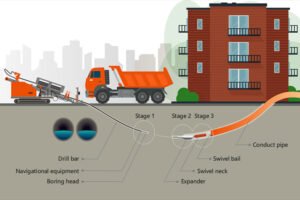

In the world of Horizontal Directional Drilling (HDD), some tools don’t get enough credit – and barrel reamers are definitely among them. These specialized tools have been quietly revolutionizing how we expand pilot bores to accommodate pipelines, especially in challenging soft ground conditions where many HDD projects face their biggest tests.

From Humble Beginnings to Modern Marvels

The story of barrel reamers began in 1990, born out of necessity. As drilling rig technology advanced rapidly, existing down-hole tools simply couldn’t keep up. This gap sparked innovation, leading to the creation of specialized tools like the barrel reamer.

What started as a basic hole enlargement tool has evolved into a sophisticated piece of engineering. Modern barrel reamers now feature full diameter compaction, fixed conical carbide cutters, and a flat face design with precisely arranged carbide cutters that enable controlled hole enlargement beyond the tool’s own diameter.

What Makes Today’s Barrel Reamers So Effective?

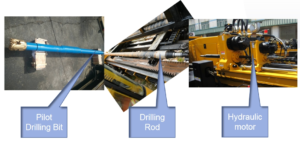

Today’s barrel reamers are packed with smart features that make them incredibly efficient:

- Front and rear fluid nozzles that improve spoil displacement

- Internal baffle systems that optimize drilling fluid distribution

- Replaceable fluid ports that extend tool lifespan

- Fixed conical carbide cutters with precise overcut specifications

- Special wear bars with carbide hard surfacing

The internal baffle system is particularly clever – it actually requires less drilling fluid, making the tool lighter and easier to handle. Meanwhile, the fixed conical carbide cutting teeth maintain an overcut design that allows slurry to flow smoothly past the reamer, significantly extending the tool’s service life.

Choosing the Right Tool for the Job

Selecting the appropriate barrel reamer isn’t a one-size-fits-all decision. Several factors come into play, with ground conditions being the most critical. Proper geotechnical investigation is essential – typically involving test holes drilled 30-60 feet below the planned drill path. For projects extending beyond 1,000 feet, soil test borings at 500 to 700-foot intervals become necessary.

When it comes to sizing, here’s a simple rule: your reamer’s diameter should be at least 1.5 times the widest product pipe you’re installing. So for a 4-inch product installation, you’ll need at least a 6-inch reamer diameter.

Keeping Your Tools in Top Shape

Regular maintenance isn’t just recommended – it’s essential for maximizing your HDD project efficiency. A well-structured maintenance routine can significantly extend your tools’ lifespan and maintain peak performance.

Here’s a practical maintenance schedule:

Daily Tasks:

Inspect threads and grease connections

Check fluid ports for blockages

Weekly Requirements:

Examine cutter blades for wear

Assess bearing condition

Monthly Activities:

Review shaft integrity

Check connection quality

After each bore, make sure to clean and flush the reamer thoroughly to remove sand, mud, and grit from all surfaces, seals, and bearings.

Knowing When to Replace

Understanding wear patterns can save you from costly downtime. Keep a close eye on these indicators:

- Transmitter housing should be replaced when wear exceeds 1/8 inch

- Shafts need checking for diameter changes, shoulder belling, thread quality, and flaring patterns

- Connections with gaps larger than 1/16 inch indicate potential problems

- Starter rods with significant hourglassing require immediate replacement

- Drill bits should be replaced when carbide buttons lose their original shape

- Swivels need regular checks for cracks or unusual wear patterns

The Future is Smart

Modern barrel reamer technology continues to evolve, incorporating advanced computer modeling and sophisticated surveying techniques. GPS systems and precision drilling sensors are making operations more efficient than ever while helping control costs.

Whether you’re working in soft soils, sandy conditions, or mixed ground, today’s barrel reamers offer specialized setups for virtually any scenario. By choosing the right tool and maintaining it properly, you’re not just completing projects – you’re building a reputation for reliability and efficiency.

SHARE:

More Posts for You

- Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

- No More “Open Surgery” for Cities: The HDD Technologies Making It Possible

- The Heartbeat of HDD: A Deep Dive into the Mud Pump

- Barrel Reamers Plays An Important Role in Modern HDD Operations

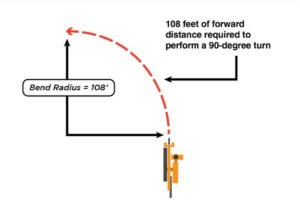

- Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

- All Terrain Drilling: The Smarter Way to Drill Through Rock

- How One-Piece Fluted Reamers Conquer Tough HDD Jobs

- Horizontal Directional Drilling Rig Operating Procedures