Buying HDD Equipment from China? The Batch Shipping Strategy Explained

The global demand for trenchless technology is booming, and China has become a powerhouse for manufacturing high-quality, cost-effective Horizontal Directional Drilling (HDD) equipment and parts. From robust drilling rigs and powerful mud motors to essential consumables like drill bits and reamers, sourcing from China can offer significant advantages.

However, one critical question often arises during the purchasing process: “Should I ship my entire order at once, or would it be better to split it into multiple batches?”

The answer isn’t a simple yes or no. It’s a strategic decision that hinges on balancing cost, risk, and project timelines. Let’s break down the key factors to help you make the right call.

The Case FOR Batch Shipping

Splitting your order into several shipments can be a savvy move for several reasons:

- Risk Mitigation: Shipping, especially by sea, carries inherent risks like delays, damage, or even loss of cargo. By splitting your order, you avoid putting “all your eggs in one basket.” If one batch is delayed, you still have other parts arriving or in use.

- Cash Flow Management: A full-container load (FCL) of heavy HDD equipment requires a significant upfront payment for both the goods and the shipping. Batch shipping allows you to stagger these costs, easing the pressure on your cash flow.

- Flexibility for Urgent Needs: Did a project suddenly require a specific drill head or a replacement mud pump? You can air freight a small, critical batch for urgent needs while shipping slower, non-essential items by sea. This hybrid approach keeps your projects on schedule.

- Easier Logistics & Handling: Receiving a 40-foot container filled with tons of equipment requires significant space, manpower, and equipment for unloading. Smaller batches are simply easier to receive, inspect, and store in your warehouse.

- Testing Supplier Reliability: If this is your first time working with a new Chinese supplier, placing a smaller initial order allows you to verify the product quality and the supplier’s professionalism before committing to a much larger, riskier shipment.

The Case AGAINST Batch Shipping (The Power of Consolidation)

While batch shipping has its perks, a single, consolidated shipment is often the default for a reason:

- Lower Overall Shipping Cost: This is the biggest advantage. Ocean freight charges are calculated per container (FCL), not per item. Filling one container is almost always cheaper per unit than shipping multiple less-than-container loads (LCL). You pay for the container space once, not multiple times.

- Simplified Logistics & Paperwork: One shipment means one set of customs documents, one bill of lading, one insurance policy, and one tracking number. This significantly reduces administrative complexity and the chance of errors.

- Faster Overall Lead Time (for the full order): While you can air freight a batch quickly, for sea freight, one consolidated shipment will get your entire order to you faster than sending it in sequential sea freight batches.

- Reduced Risk of Component Mismatch: For complex systems where components need to work together (e.g., a new power pack with specific rig connectors), receiving everything at once ensures compatibility and simplifies installation and commissioning.

Key Questions to Guide Your Decision

To determine the best strategy for your business, ask yourself these questions:

- What is the Urgency? Are you restocking general inventory, or is this for a time-sensitive project?

- What is the Nature of the Goods? Are they small, high-value parts (good for air batches) or large, heavy machinery (better for FCL)?

- What is Your Budget? Can you absorb the higher per-unit cost of batch shipping for the benefit of better cash flow?

- Do You Have Adequate Storage? Can you handle a full container’s worth of equipment at your facility?

- How Well Do You Trust the Supplier? Is this a proven partner, or a new relationship you’re testing?

A Practical Shipping Strategy

Many successful importers use a hybrid model:

- Batch 1 (Urgent/High-Value): Air freight or express courier for critical, low-volume items needed immediately (e.g., specialized electronics, seals, or pilot hole tools).

- Batch 2 (Bulky/Heavy): A full container (FCL) by sea for the core equipment—rigs, reamers, steel pipe—that is less time-critical but forms the bulk of the order’s weight and volume.

- Batch 3 (Consumables): A final LCL or consolidated sea shipment for bulky but lower-value consumables like bentonite clay or spare parts for future use.

Final Recommendation

Batch shipping is highly recommended when you are dealing with a mix of product types, have urgent needs, are managing cash flow carefully, or are testing a new supplier. It offers flexibility and risk reduction at a slightly higher cost.

A single, consolidated shipment is the most efficient and cost-effective choice for large, homogeneous orders where cost minimization is the top priority and you have the storage and capital to handle it.

Pro Tip: Always discuss your shipping plan early with your Chinese supplier. A reputable supplier will have a logistics team that can provide accurate freight quotes for both FCL and LCL options and help you devise the most efficient and cost-effective shipping strategy for your specific needs.

By carefully weighing these factors, you can turn your international HDD procurement from a logistical challenge into a competitive advantage.

SHARE:

More Posts for You

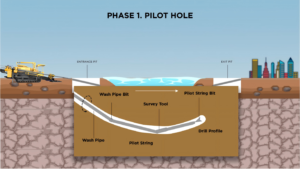

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40