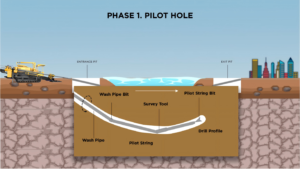

Directional Boring or Horizontal Directional Drilling

That “Stuck in the Mud” Moment

So there I was, standing in mud (again), watching a crew fight with a bore that just wouldn’t track right. The driller was getting frustrated, the locating guy was scratching his helmet, and everyone was just… stuck. We’d all been there, right?

The Blindingly Obvious Thing We All Miss

Then it hit me. We’d been talking nonstop about the drill rig’s power, the locator’s screen, the soil conditions—everything except what was actually underground: the drill string. The backbone of the whole operation. It was like worrying about a car’s paint job while the engine was knocking.

You know that moment when something obvious suddenly feels obvious? That was mine.

Your Drill String is Your Voice Underground

Directional boring—or HDD if you prefer—isn’t just about pushing forward. It’s a conversation. The ground talks back. And your drill string is your voice down there. If it’s not right, you’re basically mumbling through mud.

I used to think, “A rod is a rod.” Until I saw a good string handle a tight curve smoothly, and a cheap one just… fight it. The difference wasn’t just specs on paper. It was in the operator’s shoulders—less vibration, less wrestling. It was in the fluid returns. It was in that quiet confidence when the pipe pops up exactly where it should.

Sometimes, It’s the Simple Things

We get so caught up in the big-ticket items. The rig! The technology! But the connection between the machine and the mission? That’s your drill pipe and tools. They’re not just “consumables.” They’re your partners underground.

The “Aha!” Face (My Favorite Part)

One time, a customer told me they kept over-steering in soft clay. We chatted, not about selling, but about why. Turns out they were using a super stiff string for no real reason. Switched to something more flexible for that soil—game changer. The “aha” was on their face, not mine.

My Two Cents: Work With the Ground

So here’s my two cents: sometimes the fix isn’t more power or fancier electronics. It’s the simple thing you’re already holding. The right string for the right ground feels less like forcing it, and more like guiding it.

A Final Thought Before I Check My Boots…

Anyway, next time you’re planning a bore, maybe take a minute with your string. Look at it. Really think about what it’s about to do down there. It’s not just steel. It’s your touch, your control, your way of saying to the ground, “Okay, let’s work together.”

Just a thought from a guy who’s spent too much time in muddy fields.

Catch you on the next bore site. Maybe my boots will be dry this time (doubt it).

SHARE:

More Posts for You

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40