Horizontal Directional Drilling Rig Operating Procedures

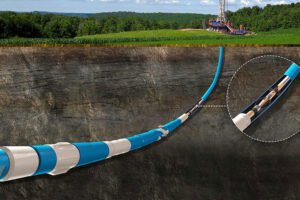

Horizontal directional drilling rig operations must strictly adhere to the principles of “safety first, precise control, and standardized procedures.” Taking into account equipment performance (e.g., torque and thrust) and the construction scenario (stratum and pipeline type), the following procedures are implemented in three phases:

Pre-construction Preparation Phase (Core: Risk Identification and Condition Verification)

Personnel Preparation

Operators must hold a Special Operations Operator Certificate and receive specialized pre-job training to familiarize themselves with the drilling rig model (e.g., torque and thrust parameters), control system, and emergency operations.

A safety and technical briefing meeting must be held before construction to clarify the drilling trajectory, stratum conditions (e.g., whether hard rock exists or underground obstacles exist), pipeline type (e.g., PE pipe, steel pipe), and safety precautions (e.g., high voltage and underground pipeline protection).

Equipment Inspection

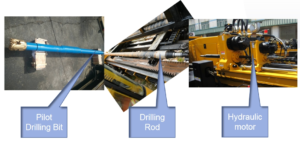

Core Component Inspection:

Drill Pipe: Based on the material properties mentioned above, inspect the outer wear of the drill pipe (≤0.1mm/100m drilling standard) and the integrity of the threaded joints (no cracks or deformation). For hard rock drilling, verify the fatigue resistance of nickel-chromium-molybdenum steel drill pipe.

Drilling Rig System: Check the power unit (engine oil level, fuel quantity), hydraulic system (oil pressure, oil leaks), guidance system (electromagnetic/gyro guidance instrument calibration, error ≤±50mm), and torque and thrust control system (no-load test run to confirm normal response).

Auxiliary Equipment: Reamer (matched to the formation; roller reamer for hard rock), mud system (mud pump pressure, mud mix ratio; in clay formations, increase viscosity to prevent hole collapse).

Site Preparation

Level the work site and ensure the drilling rig is positioned smoothly (horizontal error ≤ 1°). Set up working pits at the entry/exit points (depth equal to the pipeline burial depth + 0.5 meters, with steel plates placed at the bottom to prevent collapse).

Use ground-penetrating radar and pipeline detectors to inspect underground pipelines (gas pipes, cables, etc.) in the construction area. Mark their locations and maintain a safe distance (≥ 1 meter) from the drilling trajectory.

Set up a safety warning area (cordon off within a 5-meter radius of the work area). Equip with firefighting equipment (dry powder fire extinguishers), a first aid kit, and leak handling tools (such as oil-absorbing pads).

Operational Phase During Construction (Core: Precision Control and Dynamic Monitoring)

Equipment Commissioning

Before starting the drill rig, confirm that the operating handle is in the “neutral” position. Start the auxiliary power supply, hydraulic system, and power unit in sequence. Run the rig at no load for 5-10 minutes. Check the operating sound of each component (no abnormal noise) and the instrument display (normal oil pressure and water temperature).

Calibrate the guidance system:

Set a reference point at the entry point, enter the designed trajectory parameters (depth, azimuth), and verify in real time using the guidance instrument to ensure that the initial trajectory deviation is ≤±20mm.

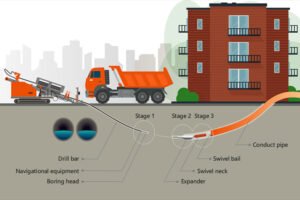

Drilling operation (divided into three steps)

(1) Pilot hole drilling Start the mud pump and inject mud into the borehole (the initial flow rate is adjusted according to the drill pipe diameter, such as 30-50L/min for a Φ114mm drill pipe), lubricate the drill pipe and prevent hole collapse;

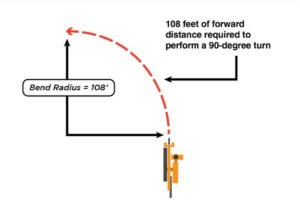

Operate the propulsion handle to control the propulsion speed (5-10m/h in conventional formations, 2-5m/h in hard rock formations), and monitor the trajectory in real time through the guide instrument. If it deviates from the design (such as depth deviation > 50mm), adjust the drilling rig inclination (±0.5°/time) to correct it. Do not turn the direction sharply;

When connecting the drill pipe, ensure that the threaded joint is clean, apply special grease (to prevent wear), and tighten it with a torque wrench according to the specified torque (such as 300-400N·m for a Φ127mm drill pipe). After connection, check the sealing (no mud leakage).

(2) Hole expansion operation After the pilot hole is penetrated, remove the reamers and install a hole expander (diameter 1.2-1.5 times the diameter of the pipeline, such as a Φ300mm pipeline with a Φ360-450mm hole expander); Start the pullback system and control the hole expansion speed (matching the mud flow to ensure timely discharge of cuttings). Hard rock formations need to be expanded in stages (first Φ200mm, then Φ300mm) to avoid excessive single hole expansion load causing drill pipe breakage; Real-time monitoring of torque and thrust. If the torque suddenly increases (such as exceeding 80% of the rated value), the operation must be suspended to check whether the drill is stuck (such as cuttings blockage). Forced operation is prohibited.

(3) Pipeline Pullback After confirming that the hole expansion is completed, connect the pipeline to be laid (such as PE pipe) to the hole expander through the pull head. The connection part needs to be treated with anti-corrosion (such as wrapping anti-corrosion tape); Start the pullback system and control the pullback speed (2-5m/h, uniform speed) to prevent the pipeline from being deformed by impact; During the pullback process, arrange personnel to patrol along the pipeline to prevent the pipeline from being damaged by friction with ground obstacles; If the pullback resistance increases (such as exceeding 70% of the rated pullback force), it is necessary to adjust the mud ratio (to improve lubricity) or suspend the inspection. It is forbidden to pull hard to prevent the pipeline from breaking.

Key Safety Operations

Operators must not leave their posts without permission during construction. Maintenance of equipment while the drilling rig is operating is prohibited. When maintenance is required, the power source must be disconnected and a “No Operation” warning sign must be displayed.

Operations must be suspended during thunderstorms or winds above force 6. The drilling rig must be grounded (ground resistance ≤ 4Ω) to prevent lightning strikes.

If an accident such as a drill pipe breakage or mud leak occurs, operations must be stopped immediately and the emergency plan must be activated. In the event of a drill pipe breakage, a guide gauge must be used to locate the breakage and a salvage plan must be developed. In the event of a mud leak, a leak-proof mat must be used to contain the leak and prevent soil contamination.

Post-Construction Processing Phase (Core: Equipment Maintenance and Site Restoration)

Equipment Maintenance

Shut down the drill rig’s power system, release hydraulic system pressure, and clean the drill pipe (use a high-pressure water jet to flush away dirt and debris from the outer wall. After hard rock drilling, inspect the drill pipe for wear and replace any that exceed the specified wear requirements promptly).

Apply anti-rust oil to the drill pipe threaded joints and hydraulic line connections, and lubricate the drill rig’s guide rails, chains, and other moving parts.

Arrange equipment such as guide gauges and mud pumps, check instrument accuracy, and record operational data (e.g., drilling time, peak torque) according to the Equipment Maintenance Manual.

Site Cleanup

Clean the mud and rock debris from the work pit. Mud must be settled (discharged after meeting standards). Solid waste (e.g., used drill pipe, packaging bags) must be sorted and recycled.

Restore the site to its original appearance: Backfill the work pit (compact in layers, with a compaction level ≥ 90%), repair any green space and road surface damaged during construction, and remove safety warning devices.

Data Collection

Collect construction records: including drilling trajectory diagrams, torque/thrust force data, pipeline pullback parameters, etc., and archive them according to GB/T 30766.

Organize acceptance inspection: The supervisor and construction company will jointly inspect pipeline position (using a guide gauge to re-measure the buried depth) and sealing (pressure test, e.g., PE pipes are pressurized to 0.8 MPa and maintained for 30 minutes with no pressure drop). Upon successful acceptance inspection, the data will be handed over.

SHARE:

More Posts for You

- Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

- No More “Open Surgery” for Cities: The HDD Technologies Making It Possible

- The Heartbeat of HDD: A Deep Dive into the Mud Pump

- Barrel Reamers Plays An Important Role in Modern HDD Operations

- Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

- All Terrain Drilling: The Smarter Way to Drill Through Rock

- How One-Piece Fluted Reamers Conquer Tough HDD Jobs

- Horizontal Directional Drilling Rig Operating Procedures