How Does Horizontal Directional Drilling Work?

Horizontal Directional Drilling (HDD) is a way to install underground pipes and conduits without digging a trench. It causes very little damage to the surface. The process is carefully planned to avoid utilities and environmental problems that are already there. It has three main steps: drilling a pilot bore, reaming the hole, and finally, installing the pipe.

The first step is to dig a hole for the entrance at the launch site.

This pit is where the drilling fluid, which is a special mix of water and bentonite clay, is kept. The fluid is pumped to the drill head to cool and lubricate the drilling assembly. It also carries away dirt and cuttings to keep the bore path clean.

A receiving pit is dug at the end of the bore path to finish it.

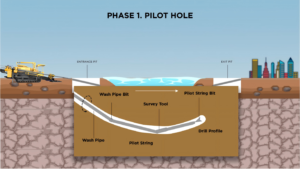

Drilling a small pilot hole along the planned path is the first step in the process. To make sure everything is right, tracking equipment is used throughout. The pilot phase is over when the drill head gets to the receiving end.

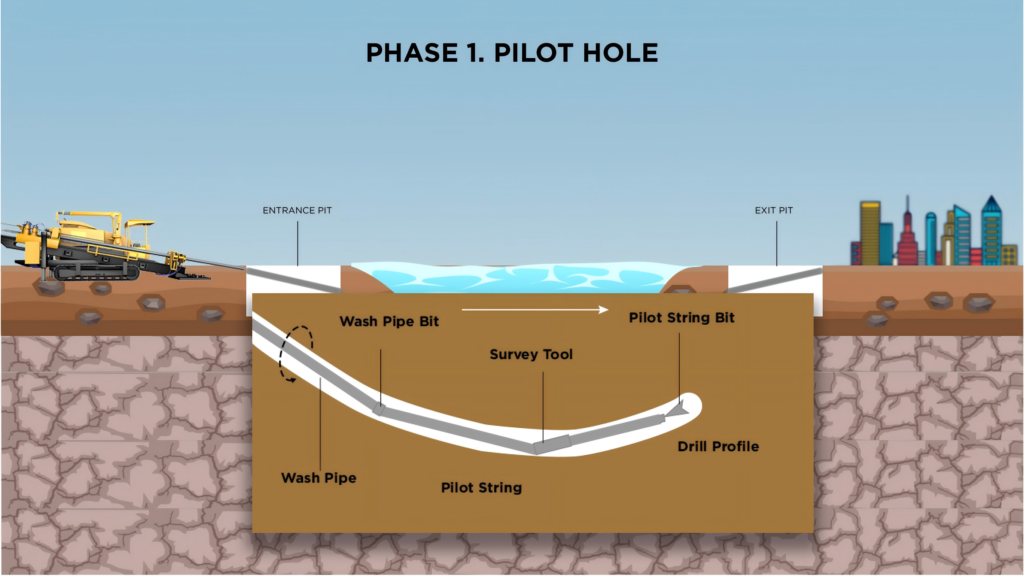

Next, you take out the drill bit and put in a reaming tool. This tool is pulled back through the pilot hole, making it bigger and bigger until it is about 1.5 times the diameter of the product pipe. To get the right size, you may need to do multiple reaming passes, depending on the project’s needs.

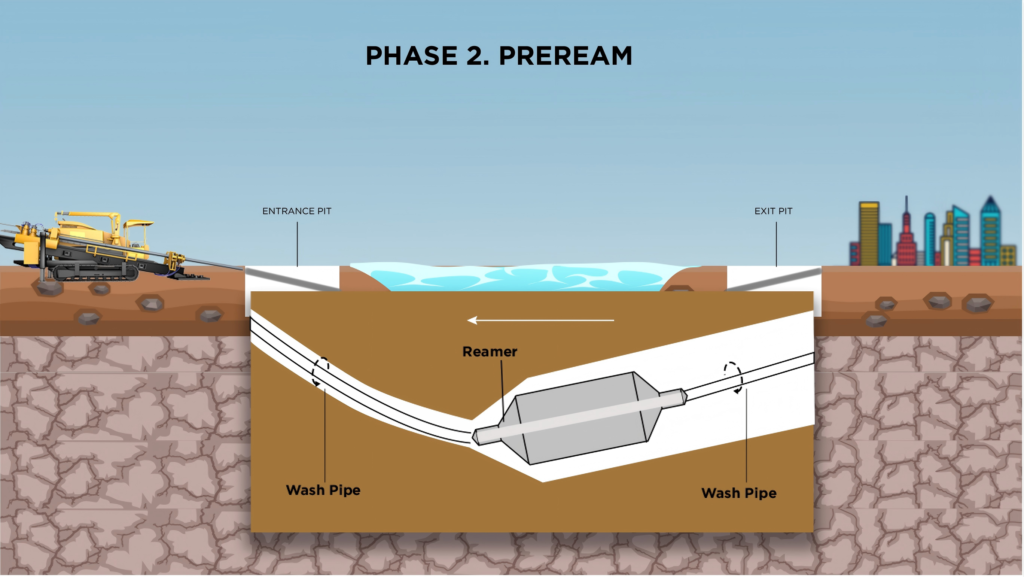

In the last step, the pipe or conduit is put together and tested for pressure above ground at the receiving pit.

Then, a special swivel connects it to the reamer, which lets the reamer turn on its own. This keeps the pipe from twisting during pull-back, making sure that the installation goes smoothly and without any twists.

Once it’s done, the new pipeline lies underground, connecting the entrance and exit pits. It’s ready to use without causing any visible problems along its path. HDD is a good choice for modern infrastructure projects because it is quick and good for the environment.

SHARE:

More Posts for You

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40