How One-Piece Fluted Reamers Conquer Tough HDD Jobs

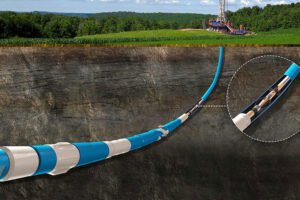

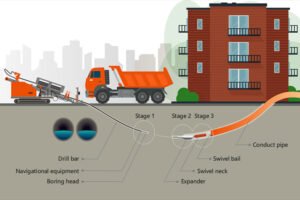

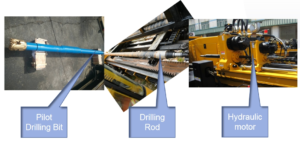

In the world of Horizontal Directional Drilling (HDD), the reamer is the unsung hero doing some of the toughest work underground. It’s not just about making a hole bigger—it’s about keeping that hole stable, ensuring drilling fluid flows smoothly, and safely guiding the pipeline home during pullback. When the ground gets tough, you need a reamer that can take the punishment without failing. That’s where one-piece fluted reamers come in—built strong, designed smart, and trusted by crews worldwide.

Why One-Piece Fluted Reamers Stand Out

What makes these reamers different? It starts with their construction. Unlike older, welded-together designs, these reamers are machined from a single piece of high-strength steel. Deep, continuous flutes are cut directly into the body, creating clear pathways for drilling fluid and cuttings. This smart design delivers real-world benefits:

- No Weak Spots: Without welded seams, there’s nowhere for cracks to start.

- No Clogging: Sticky clay or dense soil won’t jam up the works.

- Smoother Pullback: A cleaner hole means less resistance when pulling the pipe.

- Lasts Longer: Built to handle high torque and abrasive conditions, season after season.

When you pair this robust tool with well-managed drilling fluid, you get cleaner bores, fewer delays, and more productivity on every job.

Made to Fit Your Rig, No Matter the Size

/hdd-support-equipments/These reamers aren’t just tough—they’re also versatile. They’re manufactured to fit a full range of HDD equipment, from compact rigs working under city streets to heavy-duty machines drilling through rock.

Compatible with Vermeer Rigs, including:

- Compact & Mid-Range: D8x12, D10x15 S3, D20x22 S3, D23x30 S3, D23x30DR S3

- Popular Mid-Size: D24x40

- High-Power: D40x55 S3, D40x55DR S3, D60x90 S3

- Large & Pipeline: D100x140 S3, D120E, D130S, D220x300 S3, D220x500 S3, D330x500, D550

Also Compatible with Ditch Witch Rigs, such as:

- JT Series: JT5, JT10, JT20, JT21, JT24, JT28, JT32, JT40, JT60, JT100, JT120

- All-Terrain Series: AT32, AT40, AT60, AT120

Built for Any Ground—Sticky, Rocky, or Abrasive

Every drilling site is different. One day you’re in soft clay, the next in rocky ground. One-piece fluted reamers are designed to perform across all conditions:

- Clay & Sticky Soil: Deep flutes prevent clogging and keep fluid moving.

- Gravel & Cobble: The solid one-piece body stands up to vibration and impact.

- Rock & Abrasive Layers: High-quality steel and reinforced construction resist wear.

Smart Habits to Extend Your Reamer’s Life

Even the toughest tools need good care. Here’s how experienced contractors get the most out of their reamers:

✅ Inspect Regularly: Check the body, flutes, and connections before and after each job.

✅ Use Enough Fluid: Keep cuttings moving with proper flow—don’t starve the reamer.

✅ Match Size to the Job: Don’t overwork your rig or your reamer.

✅ Clean After Use: Prevent buildup that can hide damage or cause imbalance.

✅ Rotate Your Tools: Spread the wear across your fleet for longer service life.

Simple, consistent care can add hundreds of hours to your reamer—and save you time and money in the long run.

In HDD, every component counts. The reamer isn’t just another tool—it’s your partner underground. Choosing a one-piece fluted reamer means investing in reliability, efficiency, and peace of mind. Whether you’re navigating soft soils or hard rock, this is the tool built to finish the job.

SHARE:

More Posts for You

- Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

- No More “Open Surgery” for Cities: The HDD Technologies Making It Possible

- The Heartbeat of HDD: A Deep Dive into the Mud Pump

- Barrel Reamers Plays An Important Role in Modern HDD Operations

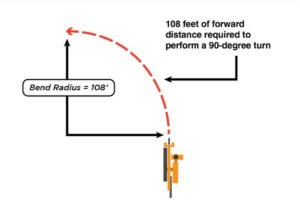

- Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

- All Terrain Drilling: The Smarter Way to Drill Through Rock

- How One-Piece Fluted Reamers Conquer Tough HDD Jobs

- Horizontal Directional Drilling Rig Operating Procedures