How to Choose the Right Welded Cone Hole Opener?

In fields such as trenchless (HDD) construction and geological drilling, welded cone hole openers are commonly used efficient rock-breaking tools. Their performance directly affects construction efficiency and cost. So, how do you choose the right cone hole opener? Today, we’ll discuss three key points to consider during selection.

Match the Cone Size to the Drill Rig

Bigger cones aren’t always better, and smaller ones aren’t necessarily worse—the key is to ensure they are compatible with your drill rig. If a small drill rig is paired with large cones, it may lead to excessive torque and slow reaming speed. Conversely, using small cones on a large drill rig can accelerate wear due to high torque, and may even cause severe failures such as “broken palms”.

Matching principles:

- 73~89mm drill pipe → pair with 6½”–8½” cones

- 102mm drill pipe → pair with 8½”–10” cones

- 127~140mm drill pipe → pair with 9½”–12¼” cones

Remember: The size of the drill rig determines the cone size. Making the right match ensures greater efficiency.

Match the Tooth Type to Rock Hardness

Different formations require cones with different tooth types. Common types include steel teeth (milled teeth) and inserted teeth (tungsten carbide inserts).

- Steel-tooth cones: These have taller teeth and are suitable for fully weathered mudstone and sandy gravel formations, allowing fast penetration.

- Insert-tooth cones: According to IADC standards, these are classified into types such as 517, 537, 617, and 637, each suited for rocks of different hardness.

Specific matching recommendations:

- Sand layers, weathered mudstone → Steel teeth

- Soft rock (<30 MPa) → IADC 517 inserts

- Medium-hard rock (40~80 MPa) → IADC 537, 617 inserts

- Hard rock (>80 MPa) → IADC 637 inserts

- Choosing the right tooth type not only improves efficiency but also extends tool life.

Determine the Number of Cones Based on Size and Rock Type

The number of cones isn’t fixed—it depends on the cone size and the hardness of the formation.

Basic principles:

- The smaller the cone, the greater the number used;

- The harder the rock, the more cones are needed.

This design ensures stronger rock-breaking capability and better stability in hard formations.

Selecting the right welded cone hole opener requires not only matching the cone size to the drill rig but also choosing the appropriate tooth type based on rock hardness and reasonably determining the number of cones. Only when all three aspects are properly addressed can construction be efficient, safe, and economical.

We hope this guide helps you in your selection process! If you have more questions, feel free to leave a comment.

SHARE:

More Posts for You

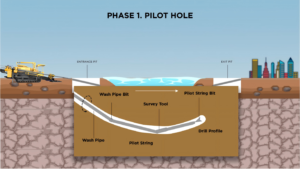

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40