Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

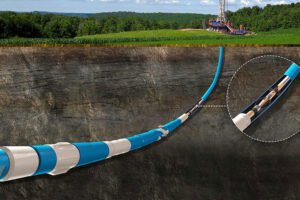

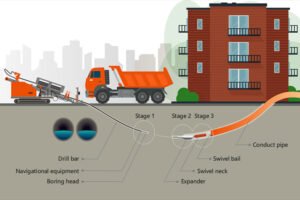

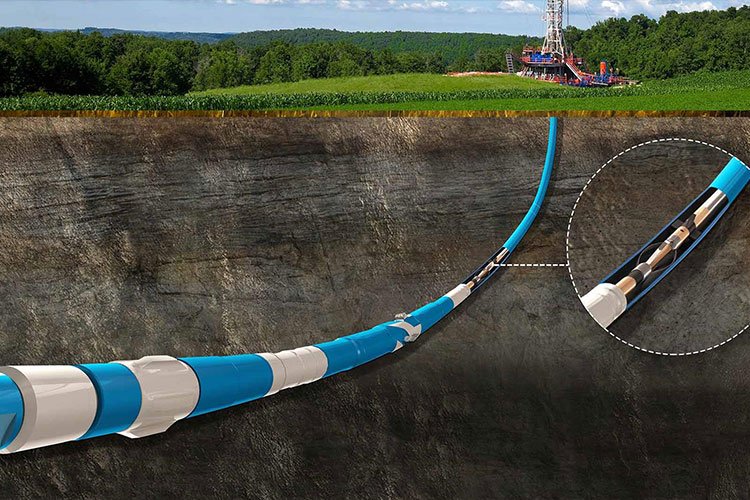

As urban underground space becomes increasingly congested, the installation of pipelines for water, gas, power, and communications inevitably encounters existing utilities, foundation piles, metro tunnels, and other subterranean structures. Traditional open-cut methods are high-risk, costly, and socially disruptive. Horizontal Directional Drilling (HDD) has become the preferred method due to its trenchless advantages, and the precise application of drill stem steering technology is the core element that ensures successful navigation around these hidden obstacles.

I. The Challenge: An Invisible “Minefield”

Underground construction is essentially performed “blind,” presenting two primary challenges:

- Detecting Obstacles: How to accurately locate the position, depth, and path of existing underground infrastructure.

- Avoiding Obstacles: How to ensure the drilling tool strictly follows a designed, safe trajectory, maintaining a safe distance from all obstacles.

Even a minor deviation can lead to catastrophic consequences, such as severing utility lines causing service outages, puncturing gas pipes leading to explosions, or damaging subway structures, resulting in significant economic loss and social impact.

II. The Core of Precision in Steering Technology

The “precision” of drill stem steering technology is manifested in three layers: Precise Perception, Precise Control, and Precise Decision-Making.

1. Precise Perception: Giving the Drill Bit “Eyes”

This is the foundation. Modern HDD achieves this primarily through Measurement While Drilling (MWD) systems.

- Wireless MWD Systems: The current industry standard. A sonde (probe) is installed behind the drill head, containing sensors that measure in real-time:

- Inclination: The drill bit’s up/down angle.

- Tool Face: The orientation of the bent housing (like the angle of a steering wheel).

- Depth: Calculated from drill pipe count and inclination.

- Temperature and other auxiliary parameters.

- Signal Transmission: Data is transmitted to a surface receiver via electromagnetic waves or mud pulses.

- Surface Location: The operator walks the surface with a walk-over locator (e.g., a “locator box” or “remote display”), which picks up the signal from the sonde to pinpoint the bit’s real-time 3D coordinates.

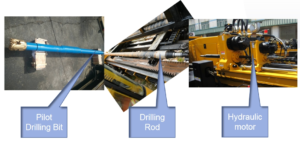

2. Precise Control: Manipulating the Drill String with “Surgical” Precision

Once the position is known, the drill bit’s direction must be controlled to correct its path.

- Mud Motor: The core component for steering. It’s a positive displacement motor powered by drilling fluid (mud) located just behind the drill bit. Its key feature is a bent housing.

- “Sliding” vs. “Rotating” Drilling:

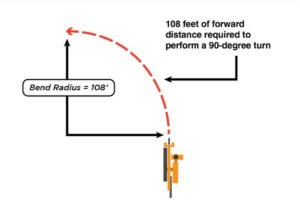

- Sliding Mode: When a direction change is needed, the operator rotates the entire drill string from the surface to align the bent housing to the desired Tool Face. Then, rotation of the drill string is stopped, and only forward thrust is applied. The bent housing causes the bit to “steer” in the intended direction.

- Rotating Mode: When drilling straight ahead or reaming, the rig both rotates and pushes the drill string. The effect of the bent housing is averaged out, and the bit progresses essentially straight.

By alternating between “sliding” and “rotating,” the operator can finely control the drill bit’s path, guiding it to “weave” around obstacles in 3D space.

3. Precise Decision-Making: Data-Driven Intelligent Planning

All perception and control data converge in the steering software on the console.

- 3D Design Path: Before drilling, a planned 3D bore path is designed in the software, avoiding all known obstacles.

- Locating System: The software compares the real-time position of the drill bit against the planned path, displaying any deviation graphically.

- Predictive Correction: Experienced operators can anticipate deviation trends and make minor corrections proactively, embodying the foresight of “precision.”

III. Precision in Practice: A Combined-Arms Approach in the Field

To successfully navigate obstacles, drill stem steering must be integrated with other technologies.

- Scenario 1: “Threading the Needle” in Congested Utility Corridors

- Strategy: Adhere to the “locate before you drill” principle. Use utility locators (e.g., CAT and Genny) to perform a detailed survey of the path before drilling begins.

- Integrated Technique: The electromagnetic signal from the steering tool can also induce a signal in nearby metallic utilities. A skilled operator can use this for “secondary verification,” ensuring a safe distance is maintained.

- Scenario 2: River Crossings and Hard Rock Drilling

- Challenge: Requires maintaining a deep, stable trajectory without undulating close to the riverbed.

- Technology Application: Use robust sondes and powerful MWD systems to ensure stable signal transmission at greater depths. Precision control enables smooth, long-radius curved drills.

- Scenario 3: Small-Diameter Pipe Jacking Alternative

- Advantage: For small-diameter pipes, HDD is more flexible and often more cost-effective than pipe jacking.

- Precision Control: High-frequency locating and micro-adjustments ensure new pipes maintain minimum safe clearances when installed parallel to or crossing other utilities like sewers and power cables.

IV. Conclusion

Drill stem steering technology has evolved from rudimentary “feel-based” drilling into a highly digital, informative, and intelligent precision control system. It is not merely a tool but a complete solution integrating physical perception, mechanical control, and digital decision-making.

By using precise perception to determine “Where am I?“, precise control to execute “Where do I go?“, and precise decision-making to plan “How do I get there?“, modern drill stem steering technology provides underground construction with the “eyes” and “skilled hands” needed to expertly navigate the complex subterranean maze. It safely and efficiently overcomes underground obstacles, providing a robust technical foundation for the modernization and renewal of our cities.

SHARE:

More Posts for You

- Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

- No More “Open Surgery” for Cities: The HDD Technologies Making It Possible

- The Heartbeat of HDD: A Deep Dive into the Mud Pump

- Barrel Reamers Plays An Important Role in Modern HDD Operations

- Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

- All Terrain Drilling: The Smarter Way to Drill Through Rock

- How One-Piece Fluted Reamers Conquer Tough HDD Jobs

- Horizontal Directional Drilling Rig Operating Procedures