The Heartbeat of HDD: A Deep Dive into the Mud Pump

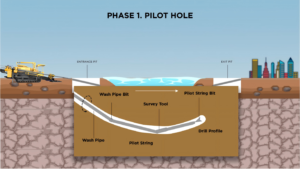

In the world of modern trenchless technology, Horizontal Directional Drilling (HDD) has revolutionized the installation of underground utilities. While the drill head and guidance systems often steal the spotlight, the true workhorse of any successful HDD operation is the mud pump. This critical component is not merely an accessory; it is the very lifeblood of the drilling process, ensuring efficiency, stability, and success from pilot hole to product pullback.

The Multifaceted Role of Drilling Fluid

To understand the mud pump’s importance, one must first appreciate the vital functions of the drilling fluid (or “mud”) it circulates. This specially engineered mixture of water, bentonite clay, and polymers is tasked with:

- Borehole Stability: The fluid pressure exerts force against the borehole walls, preventing collapse in unstable soils and supporting the structure until the product pipe is installed.

- Cuttings Removal: As the drill head advances, it generates soil and rock fragments (cuttings). The drilling fluid transports these cuttings out of the borehole, keeping the path clear for the drill string and subsequent reaming.

- Bit Cooling and Lubrication: The drilling process generates immense heat and friction. The circulating fluid cools the drill bit and lubricates the entire drill string, reducing wear and torque, and allowing for longer, more efficient pulls.

- Formation of a Filter Cake: The fluid deposits a thin, low-permeability layer (filter cake) on the borehole walls, which further minimizes fluid loss into the surrounding formation and maintains stability.

The Mud Pump: The System’s Circulatory System

The mud pump is the high-pressure heart that powers this entire process. Its primary job is to take the drilling fluid from the mixing tanks and pump it at high pressure down the hollow drill string, out through the jetting nozzles in the drill head, and back up the annular space between the borehole and the drill string, carrying the cuttings with it.

HDD operations primarily use reciprocating positive-displacement pumps, specifically triplex pumps. These pumps, with their three pistons, are favored for their ability to deliver a smooth, continuous flow and handle the high pressures required for long-distance drills.

Key Components and Specifications of an HDD Mud Pump

A typical HDD mud pump consists of:

Power Source: Usually a diesel engine or an electric motor that provides the primary mechanical power.

Fluid End: The section where the pumping action occurs. It includes the cylinders, pistons, liners, and valves that are in direct contact with the abrasive drilling fluid. These parts are designed for durability and easy replacement.

Liners and Pistons: These create the pressure and displacement. Wear is a constant factor, making them consumable items.

Suction and Discharge Manifolds: These direct the fluid into and out of the fluid end.

When selecting a mud pump, two specifications are paramount:

Flow Rate (Gallons per Minute – GPM): Determines the velocity of the fluid, which is critical for effectively lifting and transporting cuttings. A higher flow rate is needed for larger boreholes and certain soil types.

Pressure (Pounds per Square Inch – PSI or Bar): Overcomes the friction and resistance as the fluid travels through the drill string and the borehole. Longer drills and denser mud require higher pressure.

There is an inverse relationship between flow and pressure; as pressure demands increase, the pump’s flow rate will typically decrease, and vice-versa.

Choosing the Right Pump for the Job

Selecting an appropriately sized mud pump is a critical decision. An undersized pump will lead to:

Inadequate hole cleaning, causing cuttings to settle and potentially leading to a stuck drill string.

Poor borehole stability, increasing the risk of collapse.

Excessive torque and drag on the drill string.

Conversely, an oversized pump is inefficient, consuming more fuel and potentially eroding the borehole wall if the fluid velocity is too high.

Key factors influencing pump selection include:

Drill Rig Size and Torque Capacity

Total Drill Length and Diameter

Soil Conditions (e.g., sand requires better hole cleaning than clay)

Borehole Geometry

Conclusion: An Investment in Success

The HDD mud pump is far more than just a piece of supporting equipment. It is a sophisticated, high-performance machine that directly controls the hydraulic dynamics of the entire drilling operation.

Proper pump selection, maintenance, and operation are non-negotiable for achieving a clean, stable borehole and a successful, cost-effective installation. In the challenging environment beneath our feet, the reliable pulse of the mud pump is the steady rhythm that guides every project to a successful conclusion. Investing in the right pump and understanding its critical role is the hallmark of a professional and proficient HDD contractor.

SHARE:

More Posts for You

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40