What Equipment Is Used in Horizontal Directional Trenchless Drilling?

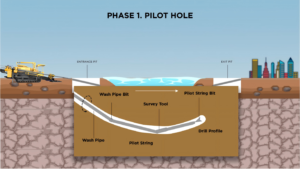

Horizontal directional drilling (HDD) is a technology that allows the laying, repair, or replacement of underground pipelines (such as water, gas, telecommunications, and power lines) without extensive surface excavation. Its equipment system is designed around the three core processes of “guided drilling – hole enlargement – pipeline pullback” and can be divided into core construction equipment, auxiliary construction equipment, and measurement and monitoring equipment. The details are as follows:

Core Construction Equipment (Core Power and Actuator Components of HDD Processes)

Core equipment directly determines drilling accuracy, construction efficiency, and applicable strata, and is the “heart” of HDD construction.

Directional Drilling Rig

The directional drilling rig is the core power device of HDD. Its primary function is to provide thrust (feed force) and torque (rotational force) to the drill tool, driving it to complete guide hole drilling, hole enlargement, and pipeline pullback. Based on the project scale and ground conditions, directional drilling rigs can be divided into three categories:

Small directional drilling rigs: Thrust of 50-150 kN, torque of 1-5 kN·m, suitable for small-diameter municipal pipelines (such as PE pipes and communication pipes, diameter ≤200 mm) and short-distance (≤300 m) construction, primarily in clay and sand formations.

Medium directional drilling rigs: Thrust of 150-300 kN, torque of 5-15 kN·m, suitable for medium-diameter pipelines (diameter 200-600 mm) and medium-distance (300-800 m) construction, capable of handling complex formations such as sand and gravel.

Large directional drilling rigs: Thrust of 300 kN or more, torque of 15 kN·m or more, suitable for long-distance (≥800 m) construction and large-diameter pipelines (such as oil and gas pipelines and water pipelines, diameter ≥600 mm), capable of penetrating rock formations (requires matching rock drilling tools).

Drilling Tool System

The drill tool is the component that directly contacts the formation, performs drilling, and pulls the pipeline. It must possess high strength, wear resistance, and torque resistance. It primarily includes:

The pilot bit: Located at the front end of the drill tool, it is responsible for breaking up the formation and guiding the drilling direction. Different drill bit configurations are designed based on the formation:

For clay/sand formations: Use a “scraper-type” drill bit (large cutting area and efficient chip removal);

For gravel/rock formations: Use a “cone-type” or “diamond compact (PDC)” drill bit (high hardness and impact resistance).

The drill bit has a built-in downhole probe (see “Measurement Equipment”) that transmits real-time position data.

The drill pipe: Connects the pilot bit to the drilling rig, transmitting thrust and torque. High-strength alloy steel pipe (such as API 5DP) is typically used. Single pipe lengths range from 3 to 6 meters and can be quickly connected using threaded connections to accommodate various drilling lengths.

Hole Opener: After the pilot hole is completed, it is used to expand the borehole diameter to 20%-30% larger than the pipeline to be laid (to ensure smooth pipeline pullback). Hole Opener is categorized by hole opening requirements:

Single-stage Hole Opener: Suitable for small-diameter pipelines (hole diameter ≤ 800mm);

Multi-stage Hole Opener: Suitable for large-diameter pipelines (requires gradual hole opening in 2-3 stages to prevent formation collapse);

Rock Hole Opener: Features alloy or PDC teeth, specifically designed for reaming in rock formations.

Pull Head: The connecting component that connects the hole opener to the pipeline to be laid. It must be strong (to withstand pullback forces) and leak-tight (to prevent mud from entering the pipeline). Common types include “clamp” and “flange” (selected based on the pipeline material).

Auxiliary Construction Equipment (Ensuring Stable Operation of Core Processes)

Auxiliary equipment primarily addresses construction needs such as “mud management,” “pipeline protection,” and “equipment lifting,” providing logistical support for HDD construction.

Mud System

Drilling (HDD) requires the injection of “mud” (typically a mixture of bentonite, water, and additives). Its core functions are to cool the drill tool, lubricate the borehole, carry cuttings, and stabilize the borehole wall. The mud system consists of the following equipment:

Mud mixing tank: This mixes bentonite, additives, and water in appropriate proportions to form a uniform slurry. The volume is typically 5-20 m³ (depending on the construction requirements).

Mud pump: This pressurizes the mixed mud into the drill pipe and ultimately ejects it from the pilot drill bit at a pressure of typically 10-30 MPa (adapted to the borehole wall pressure in different formations).

Mud purification equipment: This recovers “waste mud” returned from the drill hole, removes cuttings and impurities, and then recycles it, reducing costs and pollution. Common equipment includes:

Desander (removes sand particles ≥74μm);

Desilter (removes mud particles ≥20μm);

Centrifuge (deep purification, removing fine particles ≥5μm).

Mud recovery tank: Stores purified mud for secondary delivery by the mud pump.

Pipeline handling equipment

Used for temporary storage, docking, and protection of pipelines to be laid, preventing damage during the pullback process:

Pipeline traction frame: Fixed at the borehole exit, guides the pipeline into the borehole in a straight line, preventing deviation or bending.

Roller rack/idler: Installed along the pipeline pullback path to reduce friction between the pipeline and the ground (especially for long-distance pipelines such as PE pipes and steel pipes). Pipeline Welding/Connecting Equipment: If pipelines are insufficient in length (e.g., steel pipes or ductile iron pipes), on-site welding or connection is required. Common equipment includes:

Hot-melt welders (for joining PE and PPR pipes);

Argon arc welders (for welding steel pipes);

Electrofusion welders (for connecting small-diameter PE pipes).

Lifting Equipment

Used for lifting and moving heavy equipment such as drilling tools, pipelines, and mud tanks. Common types include:

Truck cranes: Typically have a tonnage of 25-50 tons (small HDD) or 50-100 tons (large HDD), offering flexible mobility to meet on-site lifting needs.

Crawler cranes: Suitable for lifting soft soil or large pipelines (e.g., steel pipes ≥1 meter in diameter), with a large contact area and excellent stability.

Other Auxiliary Equipment

Generators: If the construction site does not have municipal power, diesel generators (50-200kW) are required to power the drilling rig, mud pumps, lighting, and other equipment. High-pressure cleaners: Clean mud and rock debris from the drill tools and pipeline surfaces after completion.

Measurement and Monitoring Equipment (Ensuring Construction Accuracy and Safety)

The core advantage of HDD drilling is “precision directional drilling.” Professional equipment is required to monitor drilling position, mud properties, and other parameters in real time to ensure that the pipeline meets design requirements.

Directional Monitoring System

Real-time acquisition of the pilot drill bit’s position (horizontal/vertical coordinates), depth, top angle (drilling inclination), and azimuth (drilling direction) is key to controlling drilling accuracy. These systems fall into two categories:

Wireless guidance systems (mainstream): Consists of a “downhole probe” and a “surface receiver”:

Downhole probe: Built with a gyroscope, accelerometer, and magnetic sensor, it is installed within the pilot drill bit and transmits position data to the surface via electromagnetic signals.

Surface receiver: Handheld or vehicle-mounted, it receives probe signals and displays real-time parameters. The operator uses this data to adjust the drill rig’s direction (e.g., for deviation correction). Accuracy can reach ±50mm. Wired guidance systems: Suitable for construction in areas with strong electromagnetic interference (such as under high-voltage lines) or deep boreholes (≥30m). The probe transmits data directly via a cable, offering enhanced interference resistance, but also lower drill pipe connection efficiency.

Positioning and measurement equipment

Used for initial site layout (determining the borehole entry/exit locations) and later pipeline position verification:

Total stations: Accurately measure the coordinates and elevations of the entry and exit points, determining the planned borehole trajectory (horizontal direction and depth change).

GNSS positioning systems (such as Beidou and GPS): Suitable for long-distance HDD (such as pipelines crossing rivers and roads), providing real-time positioning of the drilling rig and pipeline, ensuring a deviation of ≤100mm from the planned trajectory.

Mud Parameter Monitors

Real-time monitoring of mud viscosity, specific gravity, and sand content (key performance indicators) ensures the mud can effectively carry cuttings and stabilize the borehole wall:

Viscometer: Measures mud flow resistance (typically 15-30s, adjusted depending on the formation);

Density: Measures mud density (typically 1.05-1.2 g/cm³; higher values increase drilling tool load, while lower values prevent borehole wall stability);

Sand Content: Measures sand content in the mud (required to be ≤3% to avoid wear on drilling tools and pipeline blockage).

Special Equipment for Special Formations (For Complex Construction Scenarios)

If the construction strata involve complex conditions such as hard rock, gravel, or high-water-level sand, additional specialized equipment is required:

Rock impactors: These work in conjunction with the pilot drill bit to break hard rock (such as granite and limestone) through high-frequency impact, improving drilling efficiency.

Holewall reinforcement equipment: These inject chemical slurries (such as cement slurry and chemical stabilizers) into the borehole to prevent collapse of the hole wall in high-water-level sand layers.

Fishing tools: If the drill pipe breaks or the drill string becomes stuck, tools such as “fishing spears” and “fishing tubes” are used to recover the drill string and minimize losses from construction accidents.

In summary, horizontal directional trenchless equipment requires customized configuration based on pipeline diameter, construction distance, and stratum conditions. Its core principle is to achieve minimally invasive surface construction and precise underground construction through “precise guidance + efficient rock breaking + stabilization of slurry.” It is widely used in urban renewal and pipeline construction across rivers and roads.

- Core Construction Equipment (Core Power and Actuator Components of HDD Processes)

- Auxiliary Construction Equipment (Ensuring Stable Operation of Core Processes)

- Measurement and Monitoring Equipment (Ensuring Construction Accuracy and Safety)

- Special Equipment for Special Formations (For Complex Construction Scenarios)

SHARE:

More Posts for You

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40