What Is the Difference Between Double Wall Drill Pipe and Ordinary Drill Pipe for Horizontal Directional Drilling Rig?

The core difference between the double wall drill pipe and the ordinary drill pipe (single wall drill pipe) of the horizontal directional drilling rig lies in the structural design, which leads to significant differences in medium transportation, functional adaptation, performance, and application scenarios between the two. Here are six key dimensions for comparison to help understand their essential differences:

Core structural differences (fundamental differences)

The “number of walls” of the drill pipe directly determines the internal channel design and is the basis for all functional differences:

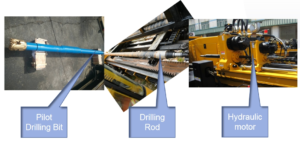

Ordinary drill pipe (single wall drill pipe): a single tubular structure with only one central channel and no distinction between inner and outer pipes. The channel simultaneously undertakes the functions of “transporting drilling fluid” and “discharging rock debris”, and belongs to the “one-way/shared channel” design.

The structure is simple, similar to a daily water pipe, with only high-strength steel walls on the outer layer and direct contact between the inner wall and the medium.

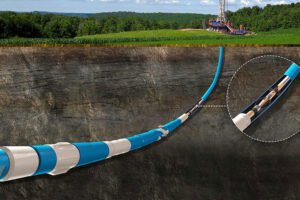

Double walled drill pipe: a double-layer coaxial structure of “outer pipe+inner pipe”, forming 2 independent channels:

Circular channel: a circular gap between the inner wall of the outer pipe and the outer wall of the inner pipe, mainly used for transporting high-pressure drilling fluid (from the drilling rig end to the drill bit);

Central channel: The hollow part of the inner tube, specifically used for discharging rock debris and returning drilling fluid (from the drill bit end back to the drilling rig).

The structure is more complex, and the inner and outer pipes need to maintain coaxiality, and the connection needs to be double sealed (to prevent liquid leakage between the annular channel and the central channel).

Differences in application scenarios (functional adaptation)

The applicable scenarios of the two are completely determined by their “chip removal ability”, “geological adaptability”, and “construction scale”, with almost no overlap:

Double walled drill pipe: suitable for “complex/large working conditions”

Strata: Complex, hard, and difficult to remove debris layers (such as pebble layers, weathered rock layers, gravel layers, or collapsing quicksand layers);

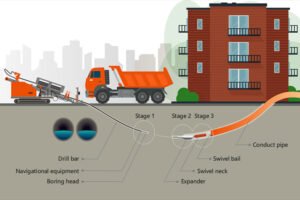

Project scale: Long distance (>300 meters, even kilometer level) and large-diameter (DN300-DN1200) construction, such as non excavation laying of cross river oil/gas pipelines and urban main pipelines;

Advantages: The closed chip removal channel can avoid rock debris pollution in the formation, and high-pressure drilling fluid can act more accurately on the drill bit (with less pressure loss in the annular channel), making it suitable for hard rock drilling.

Differences in connection methods and sealing requirements

The core of drill pipe connection is “leakage prevention”, and the complexity of sealing design varies greatly between the two due to the different number of channels:

Ordinary drill pipe: single joint connection, only requires one central seal (to prevent drilling fluid from leaking from the joint), simple joint structure (such as threaded connection, quick insertion), fast installation/disassembly speed, and low requirements for worker operation.

Double walled drill pipe: Double joint connection (requires simultaneous connection of outer and inner pipes), requiring 2 independent seals:

Outer pipe sealing: prevents high-pressure drilling fluid leakage from the annular channel;

Inner tube sealing: prevents leakage of rock debris and reflux fluid in the central channel;

The joints are mostly “flange type” or “special quick connect structure”, with high precision requirements (ensuring that the inner and outer pipes are coaxial), long installation time, and high skill requirements for operators.

Selection suggestions (summarize how to choose)

If the project involves short distances, small diameters, and simple geological formations (such as cable conduits and small water supply pipes in residential areas), ordinary drill rods are preferred for their high cost-effectiveness and easy operation.

If the project involves long-distance, large-diameter, and complex geological formations (such as river crossing pipelines, hard rock formations, and flowing sand layers), double walled drill pipes must be selected. Although the cost is high, it can avoid accidents inside the hole and ensure successful construction.

In summary, the double wall drill pipe is an upgraded version of ordinary drill pipes, which solves the core problem of chip removal in long-distance/complex formations, but at the cost of higher costs and more complex operations; Ordinary drill pipes still have a “cost-effectiveness advantage” under simple working conditions, and there is no absolute superiority or inferiority between the two, only the need to adapt to engineering requirements.

Ordinary drill pipe (single wall): suitable for “simple working conditions”

Stratum: Only applicable to soft, homogeneous, and easily detrital strata (such as silty clay, sand layers, without large grained pebbles/rock layers);

Project scale: Short distance (usually<300 meters), small-diameter (usually<DN300) construction, such as municipal small water supply pipes and cable conduits;

Limitations: Unable to cope with “rock debris deposition during long-distance construction” and “collapse of borehole walls in complex formations”, otherwise it is prone to drilling jamming and accidents inside the borehole.

SHARE:

More Posts for You

- Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

- No More “Open Surgery” for Cities: The HDD Technologies Making It Possible

- The Heartbeat of HDD: A Deep Dive into the Mud Pump

- Barrel Reamers Plays An Important Role in Modern HDD Operations

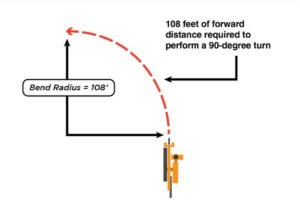

- Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

- All Terrain Drilling: The Smarter Way to Drill Through Rock

- How One-Piece Fluted Reamers Conquer Tough HDD Jobs

- Horizontal Directional Drilling Rig Operating Procedures