What Is the Main Function of HDD Blades?

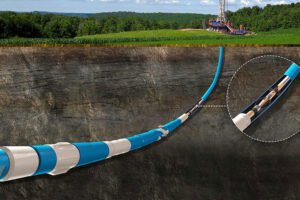

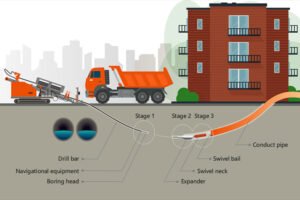

In HDD underground pipeline laying, tunnel excavation and other projects (such as horizontal directional drilling HDD, non excavation pipe jacking, micro tunnel construction), the HDD blades is the “trajectory navigation core component” of the pilot hole drilling stage – it directly determines whether the drilling tool can penetrate the complex underground environment according to the preset route, avoiding engineering rework or underground facility damage caused by deviation from the design trajectory.

Its function revolves around three core objectives of “precise directional control, stable drilling, and scene adaptation”, which can be specifically divided into the following four key functions:

Core function: Accurately guide trajectories and achieve controllable routes

The core demand of non excavation construction is to lay pipelines according to the design path without excavating the surface, and the trajectory accuracy of the pilot hole (such as horizontal deviation ± 30mm, vertical slope error ≤ 1%) is the foundation of subsequent processes.

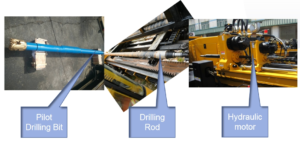

The HDD blades achieves precise guidance and correction of the drilling tool trajectory through structural design and dynamic adjustment:

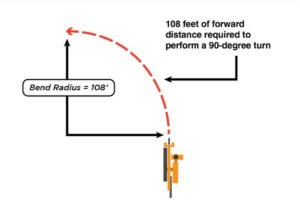

Trajectory adjustment mechanism: The HDD blades are usually linked to the “guide head” at the front end of the drilling tool, and its tilt angle can be changed through hydraulic or mechanical structure (such as 0 ° -15 ° adjustable) – when horizontal turning is needed, the HDD blades tilts towards the target direction, and uses its contact with the hole wall to “push” the drilling tool to change direction with reactive force; When it is necessary to maintain straight drilling, the HDD blade returns to a horizontal state to ensure stable axial advancement of the drilling tool.

Complex route adaptation: For scenarios where it is necessary to bypass underground obstacles (such as existing pipelines and underground structures) or meet slope requirements (such as water supply pipes requiring 1.5% downhill drainage), the HDD blades can be adjusted in real-time with a “guide device” (such as an electromagnetic guide device or gyro gyroscope guide device) to adjust the angle.

For example, in horizontal directional drilling, when it is necessary to bypass underground gas pipes, the HDD blades can be adjusted at a slight angle of 0.5 °/meter to achieve a gentle turn with a radius of 5-10 meters, avoiding damage to the drilling tool due to hard bending.

Accuracy calibration assistance: Some HDD blades are equipped with “attitude sensors” that can provide real-time feedback on the inclination and azimuth data of the drilling tool, and are linked with the ground control system. If trajectory deviation is detected (such as the drilling tool shifting downwards due to soft soil compression), the HDD blades can automatically adjust the angle slightly (such as tilting upwards by 2 °) to pull the trajectory back to the design route, ensuring the accuracy of the pilot hole.

Key function: Stabilize the posture of the drilling tool and avoid drilling shaking

Underground geology has the characteristic of “uneven softness and hardness” (such as alternating layers of soft soil and hard rock, sand layers containing isolated stones), which makes it easy for drilling tools to experience “shaking” or “deviation” due to uneven stress, resulting in irregular pore channels and trajectory deviation. The HDD blades solves this core problem by enhancing the stability of the drilling tool:

Radial support: The HDD blade is usually designed as a “ring-shaped” or “multi wing” structure (such as 3-4 symmetrically distributed wing plates), with the edge of the wing plate slightly in contact with the hole wall – during drilling, the wing plate can form a “radial support force” to limit the radial shaking of the drilling tool in the hole (such as in a 150mm diameter pilot hole, the HDD blades can control the shaking amplitude of the drilling tool within ± 5mm), ensuring that the drilling tool advances along the central axis of the hole.

Anti impact buffering: When drilling in hard rock or isolated rock formations, the drilling tool will be subjected to the back impact force of the rock, which can easily cause the drilling tool to bounce.

The “elastic flange” of the HDD blades (such as using wear-resistant rubber and metal composite materials) can absorb some of the impact force and reduce the bouncing amplitude of the drilling tool – for example, in sandstone formations with a compressive strength of 50MPa, the HDD blades with elastic flanges can reduce the bouncing amplitude of the drilling tool from 10mm to below 3mm, avoiding the “sawtooth” deviation of the trajectory due to bouncing.

Balanced stress: For asymmetric geology (such as soft soil on the left and hard rock on the right), drilling tools are prone to displacement towards soft soil layers due to excessive unilateral stress.

The HDD blades can be designed with “differentiated wing plate length” (such as extending the soft soil wing plate by 10mm) to increase the support force on the soft soil side, balance the forces on both sides of the drilling tool, and avoid posture deviation caused by uneven force distribution.

Auxiliary function: Assist in chip removal and flow guidance, ensuring smooth pore channels

Drilling through the pilot hole will produce rock debris (soil particles, rock powder, crushed stones). If the rock debris accumulates in the borehole, it will not only increase the drilling resistance, but also may cause the drilling tool to get stuck, resulting in “stuck drilling”.

The HDD blades optimizes the chip removal path to assist in ensuring smooth passage of the duct:

Flow guidance of chip removal groove: Most HDD blades are designed with “spiral chip removal grooves” (groove width 10-20mm, depth 5-8mm) on the wing plates – when the drilling tool rotates, the chip removal groove can form a “spiral thrust” to transport the rock debris towards the orifice direction; At the same time, the chip removal groove can guide the mud (cooling and lubricating medium in non excavation construction) to flow towards the front end of the drilling tool, allowing the mud and rock debris to fully mix and form a “suspension”, which facilitates the mud circulation system to pump the rock debris back to the ground.

Anti debris accumulation: The “streamlined edge” of the HDD blades can reduce the accumulation of debris on the surface of the wing plate – for example, in sand layer construction, traditional flat HDD blades are prone to a decrease in support force due to sand accumulation, while HDD blades with streamlined edges can reduce sand accumulation by more than 60%, ensuring the stable support function of the HDD blade.

Adaptation function: Compatible with multiple geological conditions and drilling tools, enhancing construction flexibility

Different non excavation processes (such as HDD, pipe jacking) and geological conditions have significant differences in the functional requirements of HDD blades. Professional HDD blades achieve multi scenario adaptation through “modular design”, reducing construction costs and replacement complexity:

Geological adaptation: For soft soil formations, a “wide wing low hardness HDD blades” (wing plate width of 30-40mm, made of wear-resistant cast iron) is used to increase the contact area with the soil and avoid the wing plate from sinking into soft soil;

For hard rock formations, a “narrow wing plate high hardness HDD blades” (wing plate width 15-20mm, surface welded tungsten carbide alloy layer) is used to improve wear resistance and impact resistance, and extend service life;

For complex formations containing isolated rocks, a “retractable wing plate HDD blade” is used – when encountering isolated rocks, the wing plate shrinks to avoid damage from the impact of the rocks. The wing plate is reset through the isolated rocks to restore stable support.

Compatibility of drilling tools: The HDD blade is designed with a “standardized interface” (such as threaded connection, flange connection), which can be adapted to different types of pilot drill bits (such as roller drill bits, scraper drill bits) and drill rods – for example, the same HDD blades can be compatible with drill rods with diameters of 100mm and 120mm, simply by replacing the adapted connecting sleeve, without replacing the entire HDD blades, improving construction efficiency.

Process adaptation: In horizontal directional drilling (HDD), a “small angle adjustable HDD blades” (maximum tilt angle of 10 °) is used to meet the requirements of long-distance smooth turns; In the construction of micro tunnels, “large angle rigid HDD blades” (maximum inclination angle of 15 °) are used to adapt to short distance fast turning scenarios (such as 90 ° turns for underground garage pipelines entering the house), ensuring trajectory control requirements under different processes.

Summary

The HDD blade is the “trajectory brain and stability center” of non excavation drilling tools – it transforms the designed route into an actual underground tunnel through precise trajectory guidance function;

Dealing with complex geological disturbances by stabilizing the posture of drilling tools;

By assisting in chip removal and adapting to multiple scenarios, construction efficiency and safety are ensured.

The essence of its function is to “connect the unknown underground environment with the predetermined engineering route”, which is the core component to achieve the advantages of “high precision, low interference, and high efficiency” of non excavation technology, directly determining the success or failure and cost control of the entire non excavation project.

- Core function: Accurately guide trajectories and achieve controllable routes

- Key function: Stabilize the posture of the drilling tool and avoid drilling shaking

- Auxiliary function: Assist in chip removal and flow guidance, ensuring smooth pore channels

- Adaptation function: Compatible with multiple geological conditions and drilling tools, enhancing construction flexibility

- Summary

SHARE:

More Posts for You

- Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

- No More “Open Surgery” for Cities: The HDD Technologies Making It Possible

- The Heartbeat of HDD: A Deep Dive into the Mud Pump

- Barrel Reamers Plays An Important Role in Modern HDD Operations

- Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

- All Terrain Drilling: The Smarter Way to Drill Through Rock

- How One-Piece Fluted Reamers Conquer Tough HDD Jobs

- Horizontal Directional Drilling Rig Operating Procedures