What Makes Dual Wall Drill Pipe a Game-Changer in HDD?

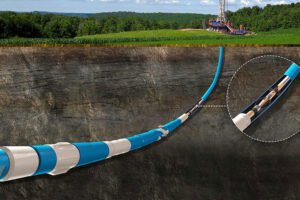

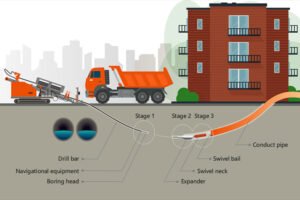

When it comes to Horizontal Directional Drilling (HDD), efficiency and precision are everything. That’s where dual wall drill pipe—also known as double wall drill rod—comes into play. This advanced tool is transforming how drilling projects are executed, especially in challenging ground conditions.

But what exactly is dual wall drill pipe, and why should you consider using it? Let’s break it down.

What Is Dual Wall Drill Pipe?

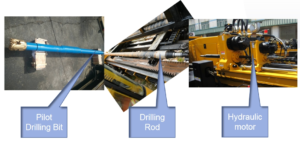

Dual wall drill pipe consists of two pipes—one inside the other—that work together to deliver torque, thrust, and drilling fluid efficiently. The inner rod transmits rotation directly to the drill bit, while the outer rod handles the push-pull force. This dual-action system allows for straight drilling, directional control, and high-speed performance even in hard rock.

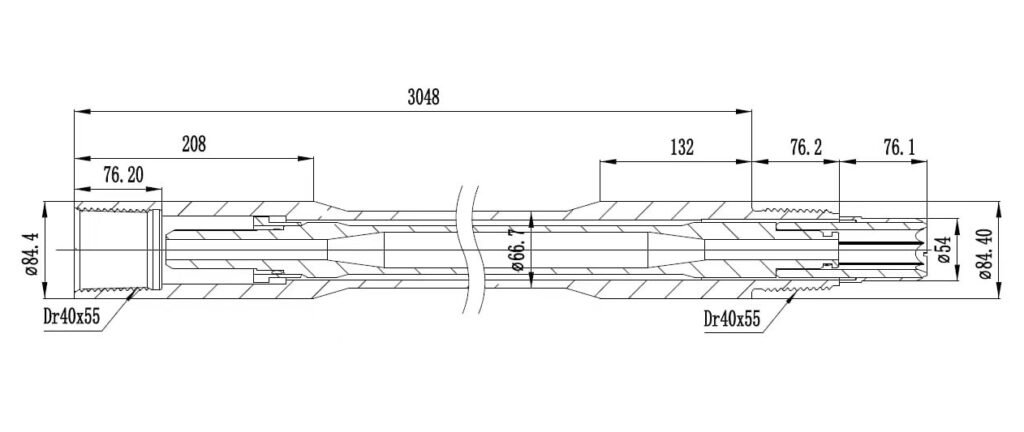

DR40x55 Drawing

Key Features & Benefits

✅ Simplified Design

- Single rotary head with a hydraulic servo system

- Easy installation and removal of rods

- Reduced mechanical complexity compared to dual rotary systems

✅ Fast & Efficient

- Achieves drilling speeds of 9–10 meters per hour in 60 MPa rock

- More than twice as efficient as traditional methods

- Lower mud consumption (0.3–0.4 m³/min vs. 1.5 m³/min)

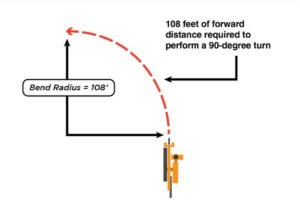

✅ Precise Directional Control

- Excellent steering capability, even in rock

- Comparable accuracy to soil-layer drilling

✅ Cost-Effective

- Simple mechanical and hydraulic systems reduce production and maintenance costs

- No external pump required

- Compact footprint on site

How Does It Work?

Dual Flow System: Drilling fluid is pumped down the inner pipe to the bit, then returns through the annular space between the inner and outer pipes.

Torque & Thrust: The outer pipe transmits torque, while both pipes work together to provide forward thrust.

Directional Capability: When a direction change is needed, the inner and outer rods can be controlled independently for precise steering.

When Should You Use Dual Wall Drill Pipe?

This tool is especially valuable in:

- Complex geological formations

- Projects requiring high drilling speed

- Situations where precise directional control is critical

- Water well, geothermal, and coal bed methane drilling

- Environments where fluid consumption must be minimized

Richdrill’s Dual Wall Drill Pipe Models

| Model | Thread Type |

| AT30 | DW2.77DS |

| AT40 | DW2.77DS |

| AT4020/AT60 | DW3.25SS |

| AT100 | DW3.44SS |

| DR40x55 | FS1#750 |

Dual wall drill pipe isn’t just an upgrade—it’s a smarter way to drill. With faster penetration, better control, lower operating costs, and versatility across various applications, it’s an ideal choice for modern HDD projects.

Whether you’re drilling through rock, installing utilities, or working on geothermal wells, this technology can help you work safer, faster, and more efficiently.

SHARE:

More Posts for You

- Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

- No More “Open Surgery” for Cities: The HDD Technologies Making It Possible

- The Heartbeat of HDD: A Deep Dive into the Mud Pump

- Barrel Reamers Plays An Important Role in Modern HDD Operations

- Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

- All Terrain Drilling: The Smarter Way to Drill Through Rock

- How One-Piece Fluted Reamers Conquer Tough HDD Jobs

- Horizontal Directional Drilling Rig Operating Procedures