Why Are Friction Welded Drill Pipes Favored by More and More Customers?

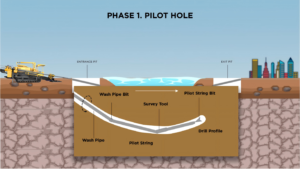

If you are about to carry out a trenchless construction, the correct choice of HDD (horizontal directional drilling) drill machine is the key to success. In addition to selecting and maintaining drill machine, drill pipe configuration is also crucial. Drill pipe is divided into one-piece forged and friction welded types. While one-piece forged drill pipe dominates the international market, friction welded drill pipe has been gaining increasing popularity in recent years. Today, we’ll uncover the five core technological advantages that have earned it the trust of global customers.

Achieved The Best Combination of Drill Rods

Through friction welding , the rod body and joints can be constructed of different materials. The rod body is constructed of high -toughness alloy steel to withstand the impact of complex formations. Joints are made of ultra-wear-resistant materials (such as 42CrMo) to withstand extreme wear . The rod body and joints undergo independent optimized heat treatments . Tempering the rod body maintains elasticity , while surface carburizing and quenching the joints increases hardness ( HRC 58-62 ). Friction-welded drill pipe achieves a fantastic combination of rigidity and flexibility, an engineering feat never achieved with a single-material drill pipe.

Long Service Life

Friction welded drill pipes have higher mechanical properties and wear resistance , and their service life is longer than that of solid drill pipes . In particular, the wear resistance of friction welded drill pipes has overturned industry perceptions:

| Comparison Item | Friction Welding Drill Rod | Integral Drill Rod |

| Joint Wear Rate | Reduced by 40%+ | Baseline Value |

| Fatigue Life | Over 500,000 Bending Cycles | ≤300,000 Times |

The joints of friction-welded drill pipes undergo a deep hardening treatment, forming a “metal armor” in the gravel formation, reducing the frequency of drill pipe replacement by 30%-50% and significantly reducing equipment downtime costs.

Good Flexibility

The friction welded drill pipe body undergoes a pre-upsetting process followed by an overall quenching and tempering heat treatment, significantly enhancing its bending resistance and flexibility . Pre-upsetting technology locally thickens the rod end by 20%-30%, eliminating stress concentration points . Gradient heat treatment creates a precise strength transition zone from the rod body to the joint .

Optimize The Internal Design of The Drill Pipe

Friction-welded drill pipe allows for the design of internal drilling fluid pathways . The threaded internal bore channel is designed to minimize hydraulic losses, particularly at the threaded connector, thereby improving the efficiency of the drilling fluid system . For example, the threaded area is de-stepped, eliminating the turbulent dead zone found in traditional joints. Measured results: In 89mm drill pipe, pump pressure losses are reduced by 18%-25%, while drilling speed increases by 15% at the same power level, significantly reducing energy costs.

Lifetime Warranty On Welds

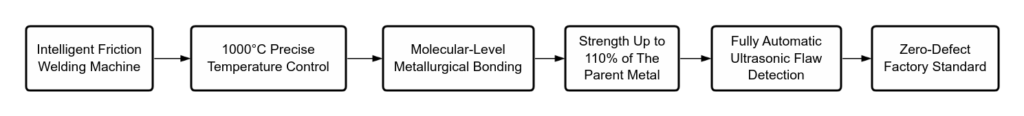

We are confident in offering a lifetime weld warranty, based on the technological advancements in friction welding technology :

According to third-party testing, the tensile strength of the weld area is ≥965MPa and the impact energy reaches 80J, truly realizing the industry myth that “the weld is stronger than steel.”

As a professional friction welded drill rod supplier, ZHE has 20 years of industry experience, advanced production equipment, and a strict quality control system. We are committed to providing customers with high-quality, high-performance, cost-effective friction welded drill rods and comprehensive technical service support.

Want to learn more about friction welded drill rod specifications, application examples, and how to customize the optimal solution for your project? Please feel free to contact us.

SHARE:

More Posts for You

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40