Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

That Packing Moment

So, I was packing a shipment of drill rods the other day for a customer with a Ditch Witch JT30, and it hit me—like, really hit me—how specific this stuff can get. I mean, five years ago when I started this gig, I kinda thought a rod was just… a rod. You know? Like, metal tube, threads on both ends, good to go.

The “It’s Not the Machine” Call

Then reality kicked in. I remember this one time early on, a buddy of mine (yeah, a customer who turned into a friend) called me frustrated. His JT30 was acting up—lost torque, steering felt sluggish. He was ready to blame the machine. We ran through the usual checks, and finally landed on the rods he was using. Turns out, they looked fine, but they weren’t quite the right fit for the JT30’s power curve and thread type. After swapping them out, he texted me: “Dude, it’s like driving a new truck.”

That was my “aha” moment. Not all drill rods are created equal, even for a compact rig like the JT30.

Why Your JT30 Deserves a Thoughtful Match

The JT30’s a solid, nimble machine—perfect for those utility lines, fiber optics, or short bores in tight spaces. But that also means every component has to pull its weight without overloading the system. The rods you match with it need to be tough enough to handle the job, but also balanced so you’re not forcing the machine to work harder than it should. It’s like putting the right tires on a 4×4. You wouldn’t throw giant mud tires on a light pickup for city driving, right?

What I Actually Look For Now

Here’s what I’ve learned since that call:

- Threads matter more than you think. A clean, precise connection keeps your torque where it should be and avoids unnecessary wear. If it doesn’t thread smoothly, don’t force it—that’s your cue to check compatibility.

- Weight and length play nice with the JT30’s design. Too heavy or too long, and you lose some of that agility the machine is known for.

- It’s not just about “fits.” It’s about how the rod behaves during the bore. A good rod for the JT30 feels like an extension of the rig, not just a tool attached to it.

No Hard Sell, Just Real Talk

I’m not here to tell you “our rods are the best” — honestly, the best rod is the one that keeps your machine running smoothly and gets your job done without drama. Sometimes that’s ours, sometimes it’s another brand. But what I can say is: if you’re running a JT30 and you’ve ever felt like it’s not performing like it used to, maybe take a closer look at those rods. Are they truly meant for your rig? Or are they just… rods?

Give It a Thought

Anyway, next time you’re gearing up for a project, think about that match. It sounds small, but it can make your whole day smoother. And if you’ve had your own “rod realization” moment—good or bad—I’d love to hear it. Shoot me an email or leave a comment. We’re all in this muddy, noisy, awesome field together.

SHARE:

More Posts for You

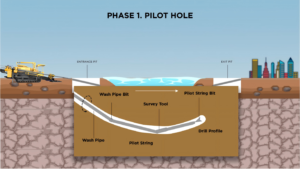

- How Does Horizontal Directional Drilling Work?

- Don’t Underestimate a Can of Grease: It’s the “Lifeline” of Your HDD Drill Pipe

- What Should I Pay Attention to When Using Mud Motors in HDD Drilling?

- Why Are Friction Welded Drill Pipes Favored by More and More Customers?

- How to Choose the Right Drill Rod for Your Horizontal Directional Drilling Project?

- From Overwhelmed to Confident: How to Choose a Pump That Actually Works for You

- Why the Right Rod Isn’t Just “Any Rod” for Your Ditch Witch JT30

- HDD Drill Rods for Vermeer 24×40