Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

If you work in horizontal directional drilling, you’ve probably heard this warning: “Don’t exceed the bend radius of your drill pipe, or it will fail instantly.” While this makes for a dramatic safety lesson, the reality is far more subtle – and in some ways, more dangerous.

The Truth About Bend Radius Exceedance

Yes, drill pipe can and will fail immediately if severely oversteered and compromised. But here’s what many don’t realize: this isn’t an “either/or” situation where the pipe either breaks or remains perfectly fine.

In most cases where bend radius is exceeded, the damage process has simply been initiated. The operator may not even know it occurred because there are no obvious signs or visible damage. If the pipe maintains its memory (its ability to return straight after bending) and shows no damaged connections, you’d never suspect the pipe has been compromised.

The Silent Killer: Progressive Damage

The real danger lies in what happens next. As you continue using the compromised pipe, metal fatigue and microfractures continue to worsen until the pipe ultimately fails. The most frustrating part? This failure can occur on what would be considered a very easy bore, leaving the driller perplexed about the cause.

This often leads to questions like:

“Why didn’t we get the same life from this drill pipe as our last string?”

“Did we receive defective steel or pipe?”

The truth is, the damage was likely done earlier when the bend radius was exceeded – you just didn’t know it at the time.

The Critical Misunderstanding About Bend Radius Itself

There’s another common misconception that compounds the problem: many drillers and industry professionals misunderstand how bend radius is actually measured.

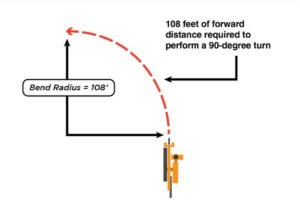

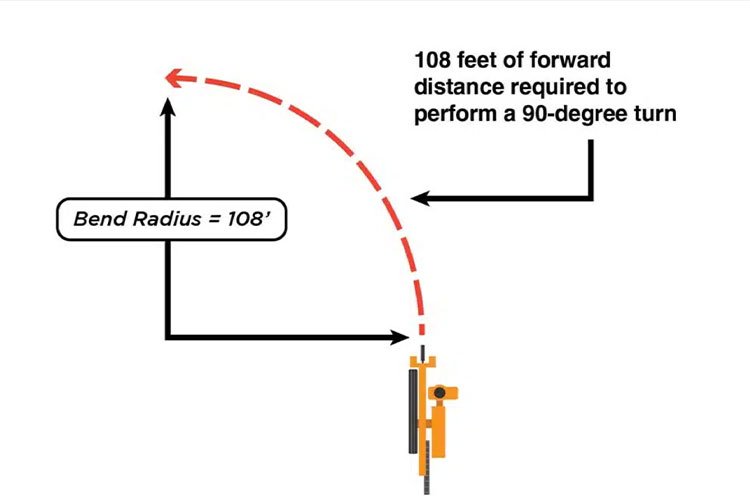

What many think: Bend radius is the amount (in feet) of pipe needed to make a 90-degree turn.

The reality: Bend radius is the amount of forward distance (in feet) required to perform a 90-degree turn.

This misunderstanding alone could explain many field problems with drill pipe.

The Bottom Line: Prevention Beats Reaction

Once bend radius has been exceeded and the pipe compromised, ultimate failure can occur anytime thereafter. It may not happen immediately, but one thing is certain: you’ll be replacing your drill string sooner – potentially much sooner than you should be.

This is why understanding your drill pipe’s true bend radius, combined with proper setback procedures and careful bore path planning, becomes so crucial. It’s not just about avoiding immediate breakage – it’s about ensuring the long-term health and cost-effectiveness of your equipment.

SHARE:

More Posts for You

- Navigating Underground Obstacles: The Precision Application of Drill Stem Steering Technology

- No More “Open Surgery” for Cities: The HDD Technologies Making It Possible

- The Heartbeat of HDD: A Deep Dive into the Mud Pump

- Barrel Reamers Plays An Important Role in Modern HDD Operations

- Your Drill Pipe Doesn’t Immediately Break When You Exceed Its Bend Radius

- All Terrain Drilling: The Smarter Way to Drill Through Rock

- How One-Piece Fluted Reamers Conquer Tough HDD Jobs

- Horizontal Directional Drilling Rig Operating Procedures